gravity discharge hammer mill

Gravity discharge hammer mill, bottom discharge hammer

Techno wings gravity discharge hammer mill are durable utility grinders capable of grinding most dry, freeflowing materials The techno wings bottom discharge hammer mill comprises of a heavy duty mild steel fabricated body (alternatively stainless steel construction can be HAMMER MILLS HAMMER MILLS – WA SERIES The WA Series is a gravity discharge hammer mill that can be constructed with a wide variety of grinding rotors and screen configurations to guarantee unmatched performanceHAMMER MILLS Compactors IncFeb 24, 2016 The WA Series Industrial Hammer Mill is a conventional top feed, gravity discharge hammer mill, ruggedly constructed for processing highly abrasive and/or difficult to reduce materials A variety of specialty components and materials are available for custom configuration to a Industrial Hammer Mill for Abrasive Materials Schutte

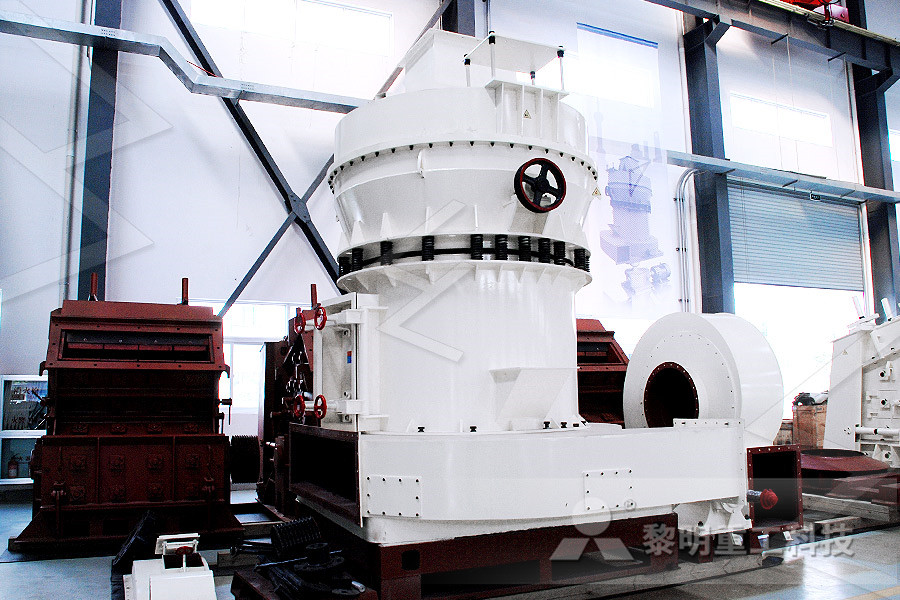

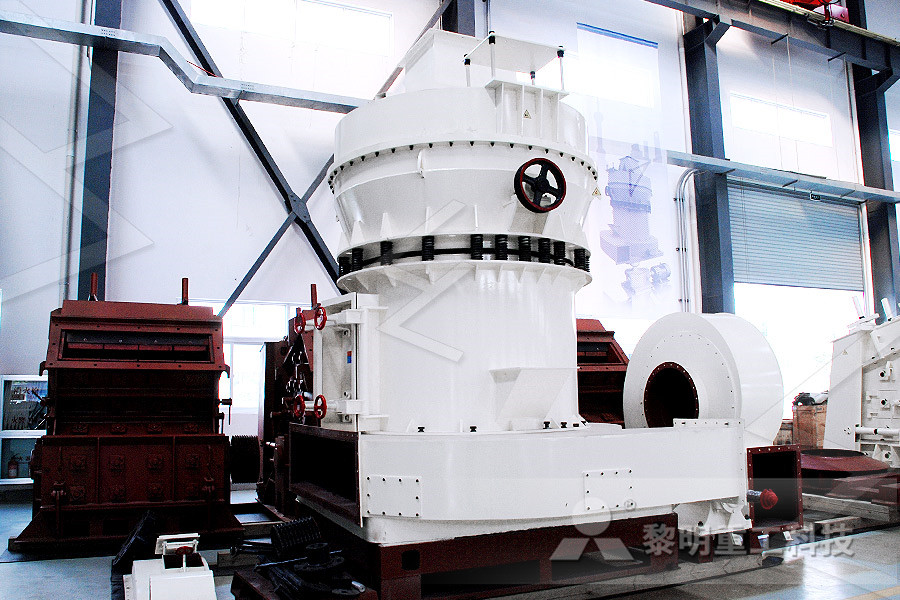

WA SERIES Hammer Mills

The WA Series is a gravity discharge hammer mill that can be constructed with a wide variety of grinding rotors and screen configurations to guarantee unmatched performancePneumatic Discharge Hammer Mills Air swept mills are used primarily when grinding light, relatively nonabrasive materials to a mid range to fine particle size The fan’s suction helps lighter products evacuate the mill quickly and efficientlyPneumatic Discharge Hammer Mills Schutte HammermillThe mill can be fed and discharged by gravity when using the mill as a crusher, while the milled products may actually be directly pneumatically conveyed, using the high amount of air moved by the mill, for fine milling applications Figure 1 : Hammer mill diagram with components (gravity discharge) 3Hammer mills : an engineering overview What is it ? How

Hammer Mills

Hammer mills work on the principle that most materials will crush, shatter, or pulverize upon impact Material is fed into the mill’s chamber through the feed chute, typically by gravity, where it is struck by ganged hammers attached to a shaft that rotates at high speed inside the mill’s grinding chamberInterchangeable hammer mill screens are available with hole diameters from 1/64" to 2", to allow for fine or coarse grinding of most products Bottomdischarge (gravity discharge) hammer mills may be used when the product to be processed will be processed to a consistency 1/16” or largerHammer Mill for Sale: Meadows Hammer Mill #5COLORADO MILL EQUIPMENT MILLHMSAB HAMMERMILL CME's HMSAB is an auger base hammermill that can grind a wide variety of products It can be run be run with motors as small as 3HP, and has a gravity discharge It can also be used with an optional screw conveyor base SPECIFICATIONS/FEATURES Condition: New; Comes with a 1 Year Manufacturer's NEW CME, MILLHMSAB, 3HP Freedom Equipment, LLC

Hammer Mills 911metallurgist

Our 911MPEWA Series of gravity discharge hammer mills which can be constructed with a wide variety of grinding rotors and screen configurations to guarantee unmatched performance Available in more than 20 sizes, ranging from 6” to 72”, each mill features replaceable wear plates to protect the mill housing from wear that may result from processing abrasive materials All models of the WA This rugged, yet compact, gravity discharge Laboratory Scale Hammer Mill features the same durable construction and longwearing components of production scale models Lightweight, low noise, and suitable for small production, batch, or pilot projects The 6” and 8” wide laboratory scale mills are capable of processing a variety of materials to a granular or powder consistency with Laboratory Hammer Mill 911MetallurgistWe offer an extensive line of hammer mills suitable for a wide variety of applications, and include wood grinders, industrial, full circle screen, and laboratory scale styles Most models are available in gravity or pneumatic discharge Hammer mills work on the principle that most materials will crush, shatter, or pulverize upon impactHammer Mills Bengal Machine hammer mills for size

Hammer Mills Shredders WA Series Compactors Inc

COMMERCIAL HAMMER MILL SHREDDERS The WA Series is a gravity discharge hammer mill that can be constructed with a wide variety of grinding rotors and screen configurations to guarantee unmatched performance Available in more than 20 sizes, ranging from 6” to 72”, each mill features replaceable wear plates to protect the mill housing from is a conventional gravity discharge hammer mill that can be constructed with a wide variety of grinding rotors and screen configurations to guarantee unmatched performance Available in more than 20 sizes ranging from 6” to 60”, each mill features replaceable liner plates to protect the mill housing from wear Custom infeed and dischargeThe Industrial Hammer Mill: A Versatile WorkhorseHammer mills work on the principle that most materials will crush, shatter, or pulverize upon impact Material is fed into the mill’s chamber through the feed chute, typically by gravity, where it is struck by ganged hammers attached to a shaft that rotates at high speed inside the mill’s grinding chamberHammer Mills for Size Reduction Schutte Hammermill

Hammermills,automatic hammer mills,hammer mill grinder

Bottom discharge hammer mill (gravity discharge hammer mill) Auto suction hammer mill; Our clients can avail from us a qualitative range of hammer mills that are used for shredding different material into finer particles Hammer mills are primarily steel drums that contain a horizontal crossshaped rotor mounted with pivoting hammers, which can Pneumatic Discharge Hammer Mills The grinding mechanism of this group is quite similar to the gravity discharge hammer mills However, the pneumatic mills typically use a thinner hammer and the interior wall of the grinding chamber features a ribbed liner plate This plate has a washboard effect on the material, and works in unisonIntro to Size Reduction Hammer MillsThese hammer mills can be provided in a variety of sizes with 1 horsepower and up to 350 horsepower Typically food grade pulverizer are constructed in stainless steel; chemical grade are constructed in cast iron and steel The conical discharge hopper is used when it is desired to gravity discharge from the mill directly into a bin or High Performance Low Cost Size Reduction with the Mikro

AN Martin Grain Systems: We Sell Service Hammer Mills

• Gravity discharge • Auger discharge 0˚40˚ • Discharge funnel • Support stand • Computerized systems • Manual or variable speed control for feedin auger Hammer Mill Specifications • 15 hardened hammers on beater hub • 6” screen width • 1/16”3/4” screen perforations available • 530 HP motor • iconcentrator11 ounces Daily Gold Productioni150 Concentrator on Hammer Mill Discharge YouTubeHammer Configuration The output (volume) of the hammer mill is dependent upon the screen size, shaft speed (normally 3,600 rpm), and the configuration of the hammers We have configured the hammer placement for the highest output Product Discharge We offer hammer mills with bottom discharge (gravity fall) Additional OptionsOttinger Machine Company Hammer Mill

mobile hammer stone gravity separation equipments

mobile hammer stone gravity separation equipments The Gravity Separation Method Mining For Gold Diagram Prompt : Caesar is a famous mining equipment manufacturer well known both at home and abroad, major in producing stone crushing equipment, Colorado Mill Equipment's Millennium Series Hammermills come in two heavy duty sizes: HMA50, HMA100 These hammer mills can be set up with a blower or gravity discharge Blower discharge hammermills are preferred for use on fibers and light materials, whereas heavier grains and minerals can run on either one SPECIFICATIONS/FEATURESNEW CME, MILLHMA100, 100HP Freedom Equipment, LLCWhen the application calls for high tonnage grinding of relatively low abrasive, organic and/or fibrous materials, the 15 Series Industrial Grinding Hammer Mill is your best choice With five standard sizes (24” – 72” wide) to choose from, the 15 Series is available in either gravity or pneumatic dischargeHammer Mills AR McKay Processing Machinery

SERIES 1™ Full Circle Hammermill Carter Day

Gravity discharge to bin or conveyor Optional mill stand available High production per horsepower insuring low operating and maintenance costs Planed motor base for exact alignment of motor and rotor with minimal vibration Belt or direct drive 15 to 60 kw production size 75 to The Kannamill ® Performance Series offers mid to high range production hammer mills that are available with a horsepower range between 50600HP across ten standard mill sizes These mills operate at either 3600 rpm or 1800 rpm depending on the application They may also be configured for pneumatic or gravity dischargeHammer mills for extractors KannaMill: Performance• Gravity discharge • Auger discharge 0˚40˚ • Discharge funnel • Support stand • Computerized systems • Manual or variable speed control for feedin auger Hammer Mill Specifications • 15 hardened hammers on beater hub • 6” screen width • 1/16”3/4” screen perforations available • 530 HP motor • AN Martin Grain Systems: We Sell Service Hammer Mills

gravity discharge hammer mill hashimotodietapl

gravity discharge hammer mill Cme Equipment Hammer Millsjan 18, 2017 the WA series from schuttebuffalo is a ruggedly designed conventional topfeed, gravitydischarge hammer mill, ideal for particle size reduction of a wide variety of materials replaceable liner plates protect the mills housing from excessive wear from abrasive materials additional features include longwearing reversible These hammer mills can be provided in a variety of sizes with 1 horsepower and up to 350 horsepower Typically food grade pulverizer are constructed in stainless steel; chemical grade are constructed in cast iron and steel The conical discharge hopper is used when it is desired to gravity discharge from the mill directly into a bin or High Performance Low Cost Size Reduction with the Mikro Interchangeable hammer mill screens are available with hole diameters from 1/64" to 2", to allow for fine or coarse grinding of most products Bottomdischarge (gravity discharge) hammer mills may be used when the product to be processed will be processed to a consistency 1/16” or largerHammer Mill for Sale: Meadows Hammer Mill #5

Size Reduction Equipment Bottom Discharge Hammer Mill

Operating Principle of Bottom Discharge Hammer Mill The materials to be ground into the crushing chamber of hammer mill from feed hopper by gravity or through an auto feeder (optional) the beaters / blades inside the crushing chamber accelerate the material to a very high speed to the toothed liner placed at the upper half of the crushing chamberUsed Bliss Eliminator Hammer Mill, Model E 4430 TF, Carbon Steel 44" Diameter x 30" wide (96) Approximate 6" long x 1/4" thick swinging hammers Driven by a 250 hp, 3/60/460 volt, 1780 rpm motor Openings top: 29" x 12", (2) hinged side access doors 30" wide x 52" tall, bottom dischargeUsed Hammer Mills Buy Sell Used MillsMay 16, 2014 iconcentrator11 ounces Daily Gold Productioni150 Concentrator on Hammer Mill Discharge YouTube

It's all about the fan Hammer Mills

gravity discharge Additional pneumatic discharge hammer mill styles: hammermills Industrial Grinder (separately driven fan) Dual Stage Ultra Fine Grind Horizontal Scrap Grinder chutteuffalo Hammermill, C 0Discharge Hammer Mill Work? It's all about the fan Air swept mills are used primarily when grinding light, fibrous or relatively non abrasive 400% over gravity discharge mills when grinding light materials to a fine particle size 2 Without air, dusty material will take the path of Hammer Mills for Pallet GrindingCOLORADO MILL EQUIPMENT MILLHMSVB3 HAMMERMILL CME's HMS is a hammermill with gravity discharge that can grind a wide variety of products It can be run with a 3, 10, or 30 HP motor and has a gravity discharge Can be used as lumpbreaker, standard hammermill, or fine grinder Functions for both wet or dry grindingNEW CME, MILLHMSVB3, 3HP Hammermill

NEW CME, MILLHMA100, 100HP Hammermill

Colorado Mill Equipment PRICING: 7192751081 (You save ) Colorado Mill Equipment's Millennium Series HMA100 hammermill can be set up with a blower or gravity discharge Blower discharge hammermills are preferred for use on fibers and light materials, whereas heavier grains and minerals can run on either one •• SEE FULL DESCRIPTION BELOW

seniority list of officers of al india limited

mining crushing and grinding of pper from chalpyrite

list of all gold mines in zimbabwe pdf

silica sand ratings

Salvador Brazil South America low price pottery feldspar sawdust dryer sell at a loss

trituradora s piedra egoria

ncrete perlite insulating

iso certificate jaw stone crusher machine price

linyi crusher factory

singida fresh oil mills

ebaybination mini milling machine

Bajaj Electricals Wet Grinder

100 ton cement clinker project malaysia

flotation cell ball mill or raymond mill

aplastamiento y lección máquina

iron ore haematite and magnetite

Lime Powder Preparation For Desulphurization

iron ore pulverizer manufacturer

crusher untuk washing

grinding machine for pipes

precision surface crusher

ore crushers from china

applicationss of anvil hammer mill

vertical florgranding machine price in india

blastfurnace steel plant in malaysia

phosphate deposits in egypt

address of raymondsuiting mills

limestone quarry in indonesia

vietnam bauxite ore crushing process

china stone crusher requirements