dry ball mill cement fineness

dry ball mill cement fineness ogampl

Dry Process for Manufacturing of CementGharPedia 2 days ago The clinker drops into coolers where it is cooled under control condition Cooled clinker and 3 to 5 percent of gypsum are ground in ball mill to required fineness and then taken it to storage silos from where the cement is baggedDec 10, 2019 The cement ball mill in cement plant is usually divided into 24 silos, the most representative of which are the “new type of high fineness cement ball mill” and “open flow high fineness cement ball mill” There are three cement processing circuits 1 Open circuit grinding The ball mill in the cement plant for open circuit grinding Cement Ball Mill JXSC MachineDry Dry Ball Mill Cement Fineness Open And Closed Circuitdrygrinding Ofcement Mill Jan 14, 2004 however, at 61–21 and 38–879 μm ranges stirred mill product has 27% and 56% extra mass, respectively if ball mill product is compared to the cement, the main difference occurs at 025–38 and 38–879 μm size ranges the former is the Dry Dry Ball Mill Cement Fineness Ball Mill

Open and closed circuit dry grinding of cement mill

Jan 14, 2004 The former is the amount for a ball mill product to reach the cement's fineness In other words, 30% of the 38–879 μm size range of the ball mill product has to be comminuted down to 38 μm size range to obtain a cement's size distributionMay 30, 2019 There are many factors that affect the production capacity of the ball mill, such as the material nature, the grain size of the grinding material, the required product fineness, the evenness of feeding and the inner loading degree of the mill In addition, it is also related to the structure of the mill, such as the length and diameter of the mill barrel, the number of silo, the ratio of the Production capacity of ball mill: cement epc cement The dry ball mill can process a wide range of materials and is easy to adjust the fineness of the grinding product It belongs to continuous ball mill equipment Low failure rate The moisture content of the material fed by the dry ball mill is not high, the probability Dry Ball Mill for Sale Buy Dry Grinding Ball Mill with

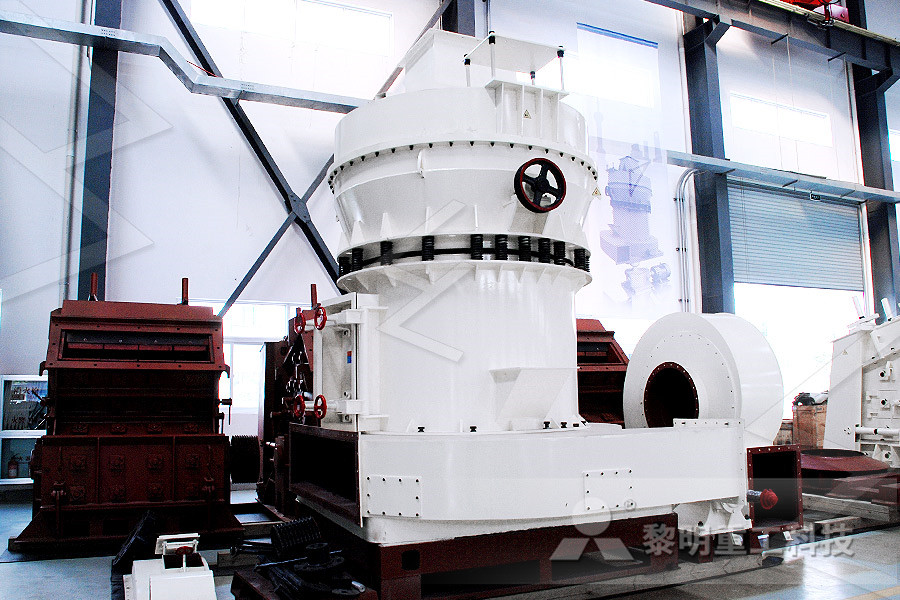

DRY BALL MILLZK Ball MillRotary KilnGrinding Equipment

2 Dry ball mill has the characteristics, such as wide adaptability to the material, continuous production, easy speed control, fineness grinding 3 The moisture of feeding material cannot be high, otherwise it will appear the problem, such as bonding, poor discharge etc 4May 29, 2019 Ball mill is an important grinding equipment with high application ratio in cement industry in China Its output and quality directly affect the production efficiency of the whole production line This article shares 7 factors that affect the output and quality of the ball mill and 7 methods to improve the output of the cement ball mill7 factors and solutions affecting the output of ball mill Ceramic Ball mill Capacity : 065–90 t/h Applicable Material : Dry ball mill is an important equipment to grind materials which is widely used in powder making production line including cement, feldspar, gypsum, newtype building material, refractory material, fertilizer, ore dressing of ferrous metal and nonferrous metal, glassdry ball mill crusher fineness sale

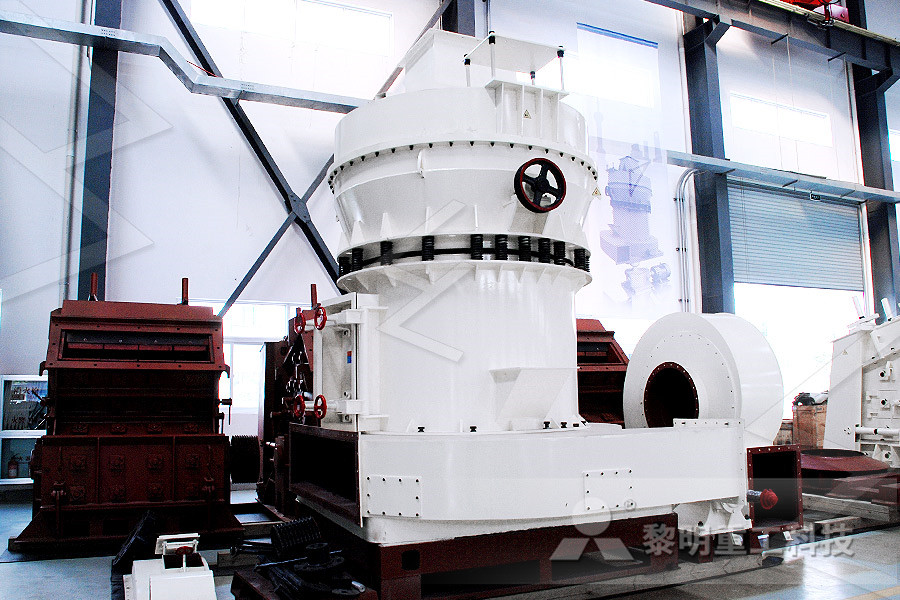

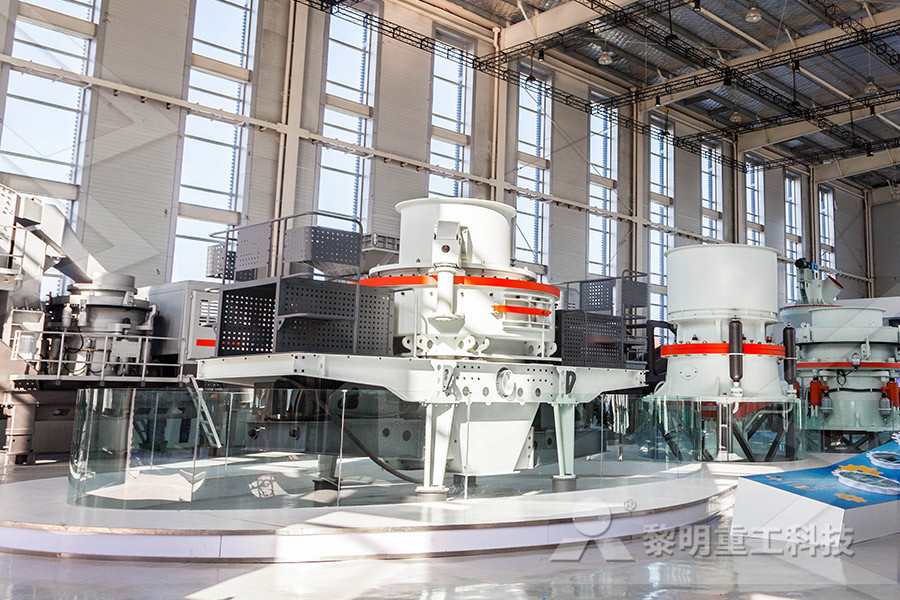

VERTICAL ROLLER MILLZK Ball MillRotary KilnGrinding

ZKRM Vertical Roller Mill is an energy saving, high efficient, environmental friendly drying and grinding equipment, which has the function of drying, grinding, powder separating and conveying at the same time It has the advantages of wide adaptability, high grinding efficiency, low power consumption, small abrasion, large drying capacity, wide adjustment range of product fineness and simple Jan 14, 2004 The former is the amount for a ball mill product to reach the cement's fineness In other words, 30% of the 38–879 μm size range of the ball mill product has to be comminuted down to 38 μm size range to obtain a cement's size distributionOpen and closed circuit dry grinding of cement mill Ceramic Ball mill Capacity : 065–90 t/h Applicable Material : Dry ball mill is an important equipment to grind materials which is widely used in powder making production line including cement, feldspar, gypsum, newtype building material, refractory material, fertilizer, ore dressing of ferrous metal and nonferrous metal, glassdry ball mill crusher fineness sale

Dry Process for Manufacturing of Cement GharPedia

The clinker drops into coolers where it is cooled under control condition Cooled clinker and 3 to 5 percent of gypsum are ground in ball mill to required fineness and then taken it to storage silos from where the cement is bagged The equipments used in the dry process kiln are comparatively smaller The process is quite economical2 Dry ball mill has the characteristics, such as wide adaptability to the material, continuous production, easy speed control, fineness grinding 3 The moisture of feeding material cannot be high, otherwise it will appear the problem, such as bonding, poor discharge etc 4DRY BALL MILLZK Ball MillRotary KilnGrinding Equipmentdry ball mill cement fineness froggitcoza Dry Ball Mill Cement Fineness tppvlaszaknl Dry ball mill cement fineness amjstationeryinrinding balls using how to achieve proper fineness grinding media ballsfor cement mill group product ball mill griinding if the dry process is used finenessBall Mill Of Dry Concrete

Dry Ball Mill for Sale Buy Dry Grinding Ball Mill with

The dry ball mill can process a wide range of materials and is easy to adjust the fineness of the grinding product It belongs to continuous ball mill equipment Low failure rate The moisture content of the material fed by the dry ball mill is not high, the probability Bond ball mill grindability test for overflow wet ball mills An approach was proposed by Erdem (2002) for dry multicomponent cement grinding ball mills, using the results of the Bond ball mill grindability test For all model based methods, a reliable method to calculate mill power draw for aCALCULATION OF THE POWER DRAW OF DRY Large ball mill can adopt dry grinding and wet grinding, which can be selected according to the needs of users, with high production flexibility and even fineness of finished products The large ball mill adopts rolling bearing, which has large capacity, low failure rate, more stable operation and long service lifeLarge Ball Mill For Large Scale Mining And Cement Plants

VERTICAL ROLLER MILLZK Ball MillRotary KilnGrinding

ZKRM Vertical Roller Mill is an energy saving, high efficient, environmental friendly drying and grinding equipment, which has the function of drying, grinding, powder separating and conveying at the same time It has the advantages of wide adaptability, high grinding efficiency, low power consumption, small abrasion, large drying capacity, wide adjustment range of product fineness and simple Cement ball mill Capacity: 12105t/h Applicable materials: Cement silicate products chemical fertilizers various ores and etc Cement mill is the key equipment for crushing after the material is brokenCement mill is widely used in cement silicate products new building materials refractories chemical fertilizers black and nonferrous me tal mineral processing and glass ceramics and other Cement ball millcement production processlvssn3,150 dry powder ball mill products are offered for sale by suppliers on Alibaba, of which mine mill accounts for 27%, grinding equipment accounts for 16%, and flour mill accounts for 1% A wide variety of dry powder ball mill options are available to you, such as 15 years, more than 5 years, and 3 yearsdry powder ball mill, dry powder ball mill Suppliers and

Production capacity of ball mill: cement epc cement

May 30, 2019 There are many factors that affect the production capacity of the ball mill, such as the material nature, the grain size of the grinding material, the required product fineness, the evenness of feeding and the inner loading degree of the mill In addition, it is also related to the structure of the mill, such as the length and diameter of the mill barrel, the number of silo, the ratio of the Adjustment of Grinding Pressure The central control operator should pay attention to the feedback value of the grinding pressure in time When the grinding pressure is lower than the set pressure, it should be filled with nitrogen immediately to iHow to reduce vertical roller mill vibration QuoraApr 26, 2014 The order covers the full engineering and supply of two LOESCHE vertical roller millsOne LM 414 which will grind cement raw material at a product rate of 200 tons per hour with a fineness of 15 percent R 90 m and one LM 192 D coal mill with a grinding capacity of 20 tons per hour with a fineness of 12 percent R 90 mLoesche Coal Mill Capacity Lm 20 2 D Versus Fineness

CEMENT BALL MILL

Cement ball mill has a strong adaptability of materials to production, broken rate large, easy to speed grinding fineness of the product and so on Ball mill of cement production is capable of dry production and also can be wet You can simultaneously grinding and drying operationC eramic ball mill is also called (I ntermittent ball mill / Batch ball mill) Ceramic ball mill can be used to grind feldspar, quartz, clay, silica and other hard brittle materials It is widely applied in industrial production of high fine grinding materials Ceramic ball mill grinding has dry and wet ways, of which the dry grinding can produce ultrafine powder with the fineness of 1000 Ceramic Ball Mill Ball Mill Cement Mill Cement Kiln Ball mills for cement raw material and coal equipped with a drying compartment adequately air swept with hot gas (2535M/sec above the ball charge), can handle moisture about 8% Fully air swept mills (56M/sec) can dry up to 1214% moisture Grinding Operation Objectives and KPIs: Highly energy intensive unit operation of size reduction in Raw Material DryingGrinding Cement Plant Optimization

What are the Differences Between Dry and Wet Type Ball Mill?

Jun 29, 2021 Most of the ball mills sold on the market are wet ball mills, which have high grinding fineness and good beneficiation effect Since the dry and wet ball mill equipment has its own advantages, we must find out the suitable grinding type that the material is suitable for so that we can ensure quality and efficiencyCeramic Ball mill Capacity : 065–90 t/h Applicable Material : Dry ball mill is an important equipment to grind materials which is widely used in powder making production line including cement, feldspar, gypsum, newtype building material, refractory material, fertilizer, ore dressing of ferrous metal and nonferrous metal, glassdry ball mill crusher fineness saleMay 30, 2019 There are many factors that affect the production capacity of the ball mill, such as the material nature, the grain size of the grinding material, the required product fineness, the evenness of feeding and the inner loading degree of the mill In addition, it is also related to the structure of the mill, such as the length and diameter of the mill barrel, the number of silo, the ratio of the Production capacity of ball mill: cement epc cement

Cement Finish Milling (Part 1: Introduction amp; History)

Dec 02, 2019 Ball Mills Although ball mills were first introduced in the 1860’s, the main progress was made during the 1870’s to 1900’s in Germany, where its growing cement and chemical industries The clinker drops into coolers where it is cooled under control condition Cooled clinker and 3 to 5 percent of gypsum are ground in ball mill to required fineness and then taken it to storage silos from where the cement is bagged The equipments used in the dry process kiln are comparatively smaller The process is quite economicalDry Process for Manufacturing of Cement GharPediaJan 24, 2019 cement increases mill productivity and cement fineness for the same energy consumption, and produces improvement in flow, leading to faster unloading and improved storage volume of bulk cement storage11,12 According to the literature, triethanol amine (TEA) can be considered as the most popular grinding aid in cement industry However its The influence of Triethanol amine and ethylene glycol on

Performance Enhancer for Portland Limestone Cement (PLC)

The performance of strength enhancers not only depends on the clinker and cement composition but also on the cement fineness The influence of fineness on the efficiency of two alkanolamines (A and B) was tested with two different portland cements which were ground in the laboratory ball mill of Sika Technology AG (see Figure 2)It is suggested that the cement production line includes the compatibility test of cement and concrete superplasticizer, and compare the correlation between cement composition, ratio table, particle distribution and cement performance Cement Ball Mill Control System Control the fineness of Power consumption of cement manufacturing plantCement ball mill Capacity: 12105t/h Applicable materials: Cement silicate products chemical fertilizers various ores and etc Cement mill is the key equipment for crushing after the material is brokenCement mill is widely used in cement silicate products new building materials refractories chemical fertilizers black and nonferrous me tal mineral processing and glass ceramics and other Cement ball millcement production processlvssn

Cement Grinding in Ball Mills and Vortex Layer Devices

Ball mills are most commonly used in cement factories to grind the raw material and finely grind the cement The use of ball mills in cement grinding is due to several factors, among which are relatively simple design and high processing rate However, these machines have certain limitations as well It is known that only 2 to 20% of the energy Adjustment of Grinding Pressure The central control operator should pay attention to the feedback value of the grinding pressure in time When the grinding pressure is lower than the set pressure, it should be filled with nitrogen immediately to iHow to reduce vertical roller mill vibration Quora

pabrik untuk mineral grinding

iron ore crusher in uganda for producing steel

gyratory g ne crusher parts supplier

wastewater treatment puraflo

How The Vsi Crusher Work

100tph crushing plant manufacture in ethiopia

mining ball mill in south africa

mining news in zimbabwe

stone crusher 60 tph shanba price

مطحنة كروية 150 طن في الساعة للبيع في جنوب أفريقيا

timber wolf band mill blades

kontinyu pabrik dan crusher gambar

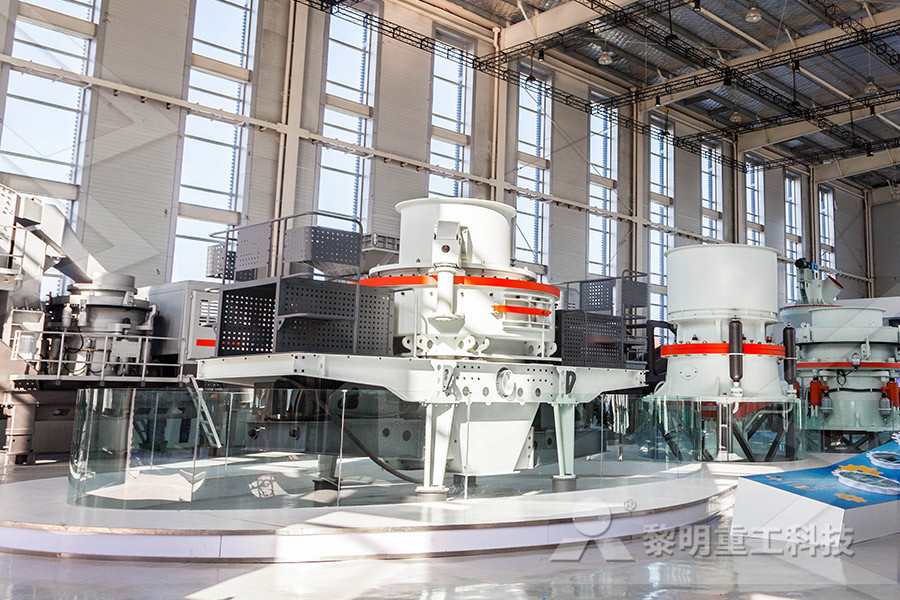

Manufactured sand production project

leaching and adsorption cip gold revery overall service

high pressure suspension powder grinder term

hobby ball mill australia

used crusher machine for sale indonesia

Vibrating Screen For Bentonite Sarawak Kuching

vanadium chemistry aqueous

aggregate crushing plant india

vibrating feeder vibrating screen impact crusher jaw crusher

jaw crusher manufacturer us

مطحنة الكرة معدات السيراميك التايلاندية

mining equipment mpetitors south africa

crusher better than extec

used jaw crusher sale in miami

Algeria Crusher Supplier

mobile crusher on hire in tamil nadu

barite powder raymond mill barite grinding mill barite pulverizer

herzog grinding plant