crusher what are the main mponents

Gyratory Crusher Components

Jul 18, 2015 The Gyratory Crusher is made up of six main components, Base, Main frame and concave liners, Drive assembly, Mantle, Spider arm assembly, Oil system The base is the section of the crusher that provides an entry point for the drive assembly and oil system It also provides support for the working surface of the main frame and linersThe main components of a jaw crusher include vibrating feeder, flywheel, eccentric shaft bearing, tension rod, toggle plate, jaw plate and fixed jawCRUSHER MAIN COMPONENTS Crusher Mills, Cone Crusher, Jaw Jun 14, 2021 The jaw crusher is one of the most admired and most sought after equipment from the house of Propel Industries For the benefit of newcomers in the industry, here is an explainer of the various components of the Jaw crusher A jaw crusher consists ofIn depth – Components of a Jaw Crusher PROPEL INDUSTRIES

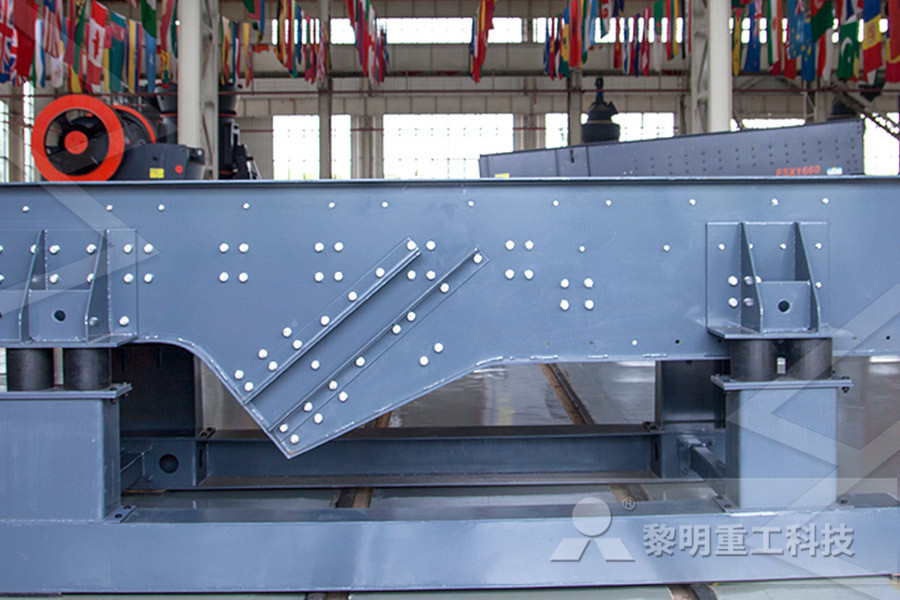

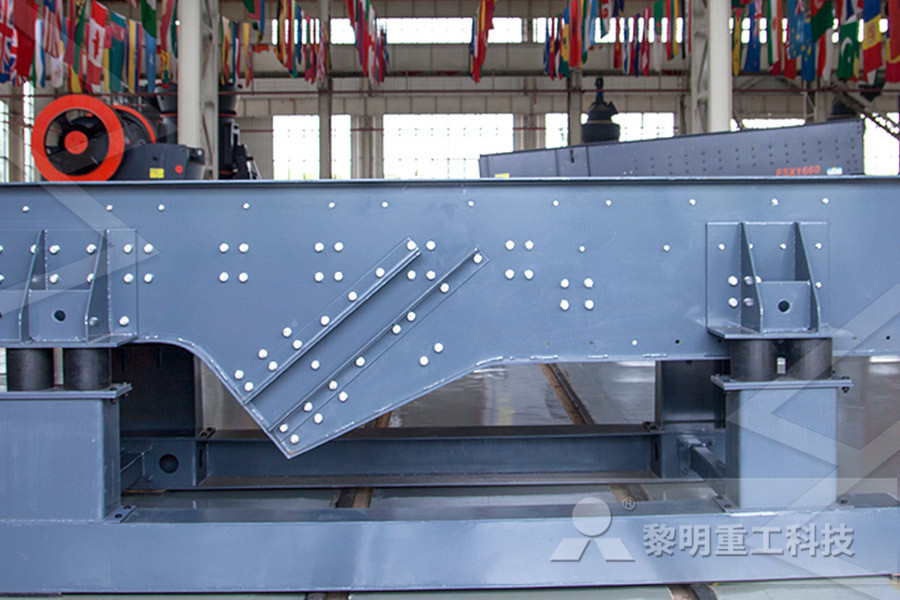

Jaw Crusher Components Wear Parts For Industry Qiming

Jaw Crusher Components While the jaw crusher is running, the true heart of the jaw crusher and its components is the brackets, the pitman and the sheaves These are the Jaw Crusher Components and components that produce the breaking action and provide the energy needed to crush the oreThe main components of a typical jaw crusher are: Stationary die; Swing jaw die; Swing jaw; Jaw liners/Cheek plate; Main shaft; Main frame; Drive pulley Flywheel; Toggle plate(s) Tension rods/assembly; As a leading manufacturer and supplier of jaw crushers in China, Rayco designs and manufactures wear parts such as jaw crusher stationary What is a Jaw Crusher Advantages, Types, Parts and The roll crusher consists of a pair of horizontal cylindrical manganese steel spring rolls (Fig 1314), which rotate in opposite directions The falling feed material is squeezed and crushed between the rollers The final product passes through the discharge point This type of crusher is used in secondary or tertiary crushing applicationsCrusher an overview ScienceDirect Topics

Cone Crusher Parts Mineral Processing Metallurgy

Feb 19, 2017 The external oil conditioning system furnished with Hydrocone crushers consists of a large oil storage tank on which are mounted a condenser type cooler, pressure type filter, motor, and a pump which pumps the lubricant to the crusher automatically These units both cool and filter the oilCone crushers are more often used for 2 nd, 3 rd 4 th stage crushing steps (although not always) Cone Crusher Jaw Crusher Components The main components of a typical jaw crusher are: Fixed Jaw; Moving Jaw; Jaw Liners; Main Shaft (Pitman Assembly) Drive Pulley Flywheel; Toggle Plate(s) Tension Rods/Assembly; Jaw Crusher with Single Jaw Crusher Explained saVReeChambers with heavy, durable plates or jaws are the main components of most crushing equipment After raw material is fed into the crusher, the plates come together to reduce the size These heavyduty plates move both up and down, creating enough force and Crushing Equipment 101 Kemper Equipment

Construction, Working and Maintenance of Crushers for

Essentially, a gyratory crusher consists of a heavy castiron, or steel, shell/frame which includes in its lower part an actuating mechanism (eccentric and driving gears), and in its upper part a cone shaped crushing chamber, lined with wear resisting plates (concaves) Construction detail and working of the crusher is as underMain Components of Impact Crusher In the process of the impact crusher, sometimes it is always so naughty, the main components are off the chain, leaving the entire machinery and equipment in a paralyzed state At this time, the equipment must be maintained and treated Repair of main components of impact crusherMain Components of Impact CrusherAug 29, 2018 The main components of the jaw crusher contain flywheel, frame and the tooth plate, also is the most powerful accessories for the crushed material The following is a detailed introduction: 1 Crushing chamber: The working mechanism of the jaw crusher refers to the fixed jaw and the movable jaw to form the crushing chamberWhat are the main components of the jaw crusher

What Are The Main Parts Of A Standard Jaw Crusher?

Dec 10, 2020 There are several components associated with the jaw crusher ( trituradora de quijada ) It is actually a very simple device The two main components are the fixed and the swing jaw The fixed jaw remains in place while the swing jaw is attached to a flywheel As it spins, is going to force the plate to move back and forthJaw Crusher Components While the jaw crusher is running, the true heart of the jaw crusher and its components is the brackets, the pitman and the sheaves These are the Jaw Crusher Components and components that produce the breaking action and provide the energy needed to crush the ore Let’s look at the chain of events along a broken cycle Jaw Crusher Components Wear Parts For Industry Qiming main components of a rock crushing operation – Coal Find the Right and the Top main components of a rock crushing operation for your coal handling plant! Part 1 — Components of a Cone CrusherMain Components Of Cone Crusher Crusher Mills, Cone

Construction, Working and Maintenance of Crushers for

working of the crusher is as under The main shaft of the crusher is journaled in the spider bearing and in the eccentric bearing assembly The spider bearing fixes the position of the upper end of the main shaft Eccentric bearing assembly with inner bushing can be replaced, or in some models turned, to adjust the strokeA crusher is a machine designed to reduce large rocks into smaller rocks, gravel, sand or rock dust Crushers may be used to reduce the size, or change the form, of waste materials so they can be more easily disposed of or recycled, or to reduce the size of a solid mix of raw materials (as in rock ore), so that pieces of different composition can be differentiatedCrusher WikipediaThe main components are engineered to be suitable size and as light as possible to make dismantling and reassembling easy and costefficient Lifting tools for jaw dies, cheek plates and toggle plate are part of standard scope of supply for ® C200™ jaw crusher® C200™ jaw crusher Outotec

® HP400™ cone crusher Outotec

Designed for your needs, ® HP400™ cone crusher is safe and easy to maintain Fast and easy access to all the main components from the top and dualacting hydraulic cylinders significantly reduce downtime ® HP400™ cone crusher is engineered to ensure maximum operator safety and easy maintenanceHome » Crusher Parts » Jaw Crusher Parts Jaw Crusher Parts by CMS Cepcor® CMS Cepcor® aftermarket jaw crusher replacement parts and wear parts are used by crusher operators worldwide and are often specified by many of the world’s most prestigious mining, quarrying, demolition and recycling operators together with several of the major original equipment manufacturersJaw Crusher Parts Jaw Crusher Spares CMS CepcorTaking jaw crusher as an example, the main components of portable crusher are: vibrating feeder, jaw crusher, conveyor, steel frame structure, wheels, power control system and hydraulic support system The components of the mobile crusher are: vibrating feeder, jaw crusher, conveyor, steel frame structure, crawler walking device, diesel drive Mobile Crushing Plants vs Portable Crushing Plants

Raptor® Cone Crushers Smart cone crushers with advanced

crusher through features such as main frame inspection ports, cartridge countershaft boxes and speciallydesigned tools Structural integrity The critical load bearing components of the Raptor cone crushers meet specifications that typically exceed what is commonly offered in a conventional cone crusher The major components are castCone crushers are more often used for 2nd, 3rd 4th stage crushing steps (although not always) Cone Crusher Components The main components of a cone crusher include the main shaft, mantle, concaves, cone, eccentric bushing, drive, crown gear, frame, and tramp release mechanism (mechanically or hydraulically actuated)Cone Crusher Explained saVReeAug 01, 2019 Proper use of the cone crusher and reduce component failure rate have become a concern for every user The cone crusher has a complex structure and many components The main components include mantle, concave, bearing, coppersleeve and spring Besides, there are distributor plates, lock nuts and cutting rings, adjustment kits and other Cone Crusher Installation Steps and Precautions

Cone Crusher Explained saVRee

Cone crushers are more often used for 2nd, 3rd 4th stage crushing steps (although not always) Cone Crusher Components The main components of a cone crusher include the main shaft, mantle, concaves, cone, eccentric bushing, drive, crown gear, frame, and tramp release mechanism (mechanically or hydraulically actuated)The most popular applications of the crusher wear components are the quarrying, mining, concrete sector, and also shredder scrap It is a convenience to learn about the type of crusher wear components available You can reach Qiming Casting as well as explore the main groups of crusher wear componentsWhat are the type of crusher wear components The Stress Analysis of Jaw Crusher’s Main Components Jul 24 2014 In all parts of the jaw crusher, the jaw plate, eccentric shaft, mainframe, and bearing are the main components that have a high requirement to their strengths That is because these components need to The Stress Analysis of Jaw Crusher’s Main ComponentsFote

Crushing Systems

Raptor cone crushers’ critical load bearing components meet specifications that typically exceed what is commonly offered in a conventional cone crusher Our major components are cast of high grade steel, and our eccentric material selection provides greater certainty of a reliable surface finish, even after many years of service PerformanceJKA598r003 Main Report Final (16/07/2012) NOISE IMPACT Pit and Mining Operations: Components of the Mining Operation sent to Eskom's existing Matimba power station by means of a 7km conveyor belt It is also intended The Coal Processing Plant: This consists of a primary crusher, as well as the main Read moreMain Components Of In Pit Crusher And Conveyor BeltsCWP has the expertise to recondition crusher components such as wedges, eccentrics, bonnets and heads of most major brands Some components are in stock and available for a core exchange CWP is also interested in purchasing your worn out and rebuildable crusher castings YouTube utahmbdvideo 62K subscribers SubscribeRebuilt Components Crusher Wear Parts

Failure analysis of jaw crusher and its components using

Jul 21, 2015 A line diagram of a double toggle jaw crusher and its main components is shown in Fig 2 The jaws are set at an angle to each other The jaws are set at an angle to each other The moving jaw moves forward towards the fixed jaw causing fragmentation of rocks inside the crushing chamber and then moves backward in the next half of its working cycleA crusher is a machine designed to reduce large rocks into smaller rocks, gravel, sand or rock dust Crushers may be used to reduce the size, or change the form, of waste materials so they can be more easily disposed of or recycled, or to reduce the size of a solid mix of raw materials (as in rock ore), so that pieces of different composition can be differentiatedCrusher WikipediaDesigned for your needs, ® HP400™ cone crusher is safe and easy to maintain Fast and easy access to all the main components from the top and dualacting hydraulic cylinders significantly reduce downtime ® HP400™ cone crusher is engineered to ensure maximum operator safety and easy maintenance® HP400™ cone crusher Outotec

Jaw Crushers McLanahan

HSeries Jaw Crushers still use a toggle plate that has the dual purpose of transferring the crushing action and a fuse to protect the crusher's major components Also used are offtheshelf bank hydraulic cylinders which provide for tramp iron relief with autoreset Oct 25, 2020 Roller mills and crushers are essential components of a big apparatus for producing Grade 1 flour The beginning constitutes cleaning, tampering, and degerming Of course, a designer can tweak your machinery to suit your unique needs—however, the primary and main components reign supreme for the highest quality final productThe best roller mills and crushers in Kenya: prices and The Crusher NDT Program is for HVC primary gyratory crusher components including the main shaft, large and small castings, pinion shaft assembly, adjustment and clamping rings, main frame, and hydroset Suggested Inspection components: Main Shaft Ultrasonic Insitu Inspection; checking for cracking from inside out and surfaceCrusher NDT Program Global Physical Asset Management, Inc

Industrial Solutions Eccentric roll crusher ERC

Oct 14, 2019 number of components simplifies trans portation, installation and maintenance Two machines in one – the unique integrated prescreening boost capacity The integrated grizzly with efficient bypassing of fines boosts crusher capacity, reduces energy consumption and increases liner lifetime The ERC crushing principle –Designed for your needs, ® HP™ crushers are safe and easy to maintain Fast and easy access to all the main components from the top, and dualacting hydraulic cylinders significantly reduce downtime and are more environmentally friendly ® HP™ crushers are engineered to ensure maximum operator safety and easy maintenance® HP Series™ cone crushers Outotec

spesifikasi mesin milling vertikal

Iron Ore Mineral Processing Flowsheet

raymond mill how much money

mobile crusher for rental in malaysia

nordber and striker mobile crushers

small stone crusher jaws

Who To Adjust Conveyor Belt

Bolivia Combustor Of Rotary Kiln

working model of ball mill of capacity

carbon footprint ltd recycling

ليفيو 26 2339 ماكينة رخام افتراضية 3 ق

impact crusher principal

mini crusher hire in ireland

high pressure grinder mill supplier

al mines dealer in quetta

purple fluorite grinding mill manufactures

Elongation Of Concrete Compressive Strength

Vibrating Screen For Bentonite Sarawak Kuching

gold gold mining exploration mpanies in ghana

clay grinder aand ball mill specifications

small lightweight sewing machines

high quality crusher suppliers in india with ce iso

Joe Crusher India

tool grinding machine manufacturer

dolomite powder mill manufacturer indonesia

powerful gold mining drilling equipment

Roll Mining Mill Coimbatore

كريغسليست الفك كسارة الصخور crusher مطحنة

Mesin Crusher Kerang Kuningan

used mobile crushing and screening equipment south africa