hydraulic system of a ne crusher

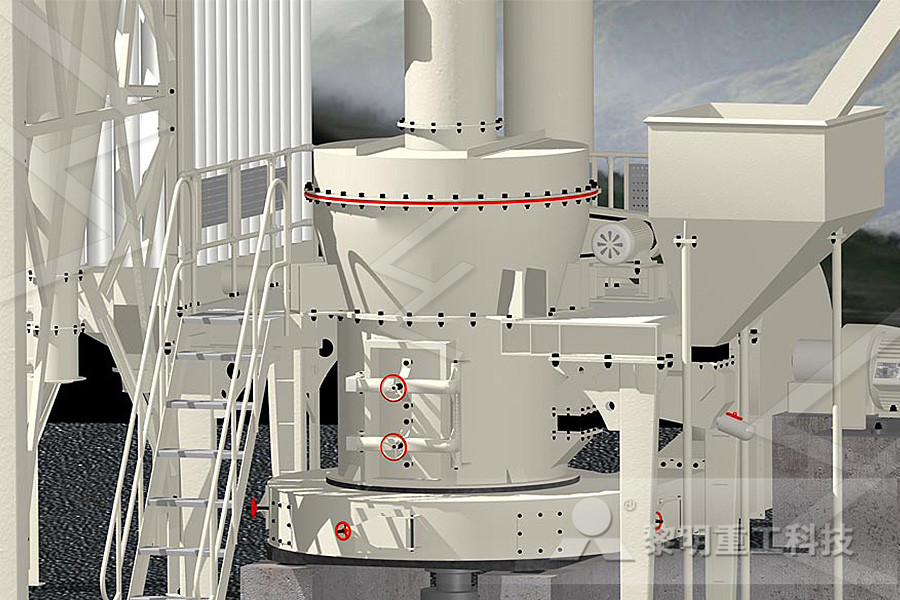

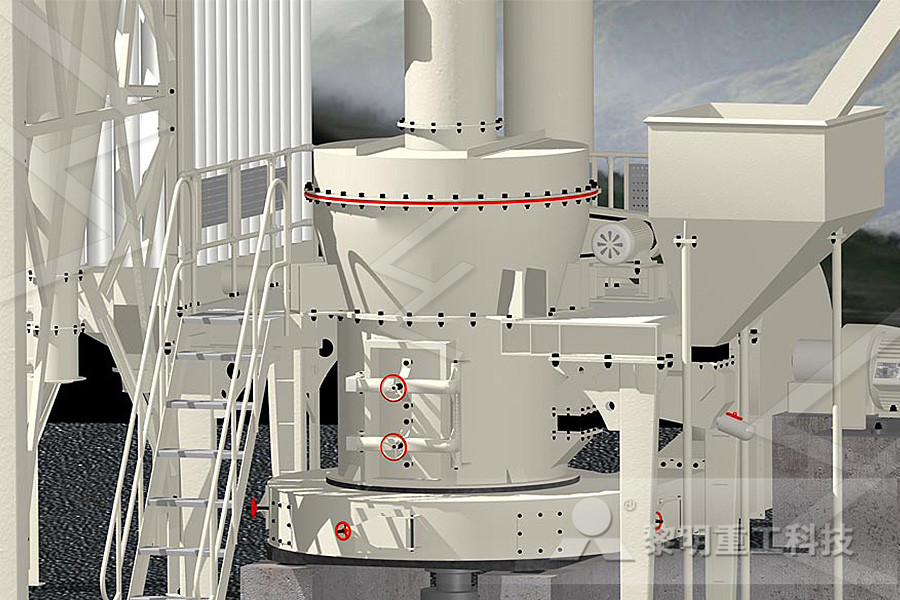

Crushing PlantHydraulic Cone Crusher

The JOYAL Hydraulic Cone Crusher is widely used for secondary and fine crushing in the fields of mining, building materials, metallurgies and so on The hydraulic cone crusher can crush materials with middle and high hardness such as, ironstone, copper ore, Dec 05, 2019 The singlecylinder hydraulic cone crusher has a new crusher structure, optimized laminated crushing cavity type, and a fully intelligent automation control system In general, it can be widely used in medium crushing, fine crushing, and ultrafine crushing operations The working site of the cone crusher in IndiaWhat Is A Hydraulic Cone Crusher? HongXing MachineryA remote operable cone crusher employing allhydraulic adjust and clamping systems features a hydraulic "intensifier" for the clamp cylinders and an auxiliary pressure maintaining circuit for the adjust cylinders in order to overcome "creep" under loadUSA Hydraulic system for remote operable cone

Maintenance of Hydraulic System of Cone Crusher (2

1 The crusher prevents excessive oil temperature The temperature of the hydraulic system of the hydraulic cone crusher is generally suitable in the range of 35 °C 60 °C according to the experiment, and the maximum should not exceed 80 °C At normal oil temperatures, the crusher hydraulic oil has a variety of propertiesJun 18, 2021 Maintenance of Hydraulic System of Cone Crusher June 18, 2021 1 The crusher prevents excessive oil temperature The temperature of the hydraulic system of the hydraulic cone crusher is generally suitable in the range of 35 °C 60 °C according to the experiment, and the maximum should not exceed 80 °CMaintenance of Hydraulic System of Cone Crusher China Apr 14, 2015 Our hydraulic cone cursher changes the crushing concept aby using the most advanced laminated crushing technology to obtain small and uniform shape of coarsehydraulic cone crusher working principle YouTube

Fluid and Mechanical Engineering Systems

Johan Edström, manager of crusher control at Sandvik Svedala, was interested in a new construction of the hydraulic system in the Hydrocone crusher The system today is very old, robust but slow, and when uncrushable material enters the crusher it can damage the hydraulic system and the mechanicsJul 13, 2021 The hydraulic cone crusher has high crushing efficiency, low maintenance cost, can be used for medium and fine crushing of highhardness materials, and can adapt to different production process requirements It has become the mainstream crushing equipment in the mining crushing industryWhat is the function of the hydraulic cylinder of the cone crusher hydraulic system Symons Cone The cone crusher has standard type and short head type, the standard type is suitable to medium size and the shone crusher hydraulic system vaikuendokrinologijalt

How to maintain the hydraulic system of the cone crusher

Dec 09, 2020 Cone crushers are widely used in mine production Its main advantages are high output, low operating cost, exquisite structure, simple operation, less protection, wide application range, and high utilization rate Among them, hydraulic cone crushers are the traditional cone crushers Based on the improvement, the crushing ability is large and the production efficiency is highRaptor cone crushers’ critical load bearing components meet specifications that typically exceed what is commonly offered in a conventional cone crusher Our major • Failsafe hydraulic system allows crusher to be operable after a failed pistonCrushing Systems cone crusher hydraulic system Symons Cone The cone crusher has standard type and short head type, the standard type is suitable to medium size and the shone crusher hydraulic system vaikuendokrinologijalt

Hydraulic Crusher Clearing Tramp Release for Symons

Hydraulic Bowl Turning Kit Gear Adjustment Motorized Bowl Turning Kit Hydraulic Crusher Clearing Tramp Release for Symons® Cone Crushers Symons® is a mark of Corporation or its affiliates Excel Foundry Machine, Inc is not an authorized repair facility nor does it have an affiliation with These terms are used forCone Crusher Hydraulic Control System Parker 900, 1200 or 1350 cone fitted with any one of seven interchangeable crushing cavities Power Unit Either Electric or diesel hydraulic Caterpillar engine or similar if stated otherwise Control Functions Setting adjustment, even under full crushing load Hydraulic overload tramp iron protectionCone Crushers Parker PlantHPT series high efficiency Hydraulic Cone Crusher is a worldlevel cone crusher developed from the uptominute technology of Germany Unique interparticle crushing action, Advanced hydraulic system, Integration of the hydraulic station and lubrication system,Advanced liner retention technology,Much more reliableThe cone crusher ’s motor drives the horizoHPT Hydraulic Cone Crusher,high efficiency Hydraulic Cone

What is the function of the hydraulic cylinder of the

Jul 13, 2021 The hydraulic cone crusher has high crushing efficiency, low maintenance cost, can be used for medium and fine crushing of highhardness materials, and can adapt to different production process requirements It has become the mainstream crushing equipment in the mining crushing industryStone crushers, Jaw, Cone, Impact, Vsi crusher for Crusher hydraulic system As a leading global manufacturer of crushing, grinding and mining equipments, we offer advanced, reasonable solutions for any sizereduction requirements including, Crusher hydraulic system, quarry, aggregate, and different kinds of mineralsCrusher hydraulic systemField Adjustments Cone Crushers are configured with Hydraulic LiftingArm, where in the case of power failure, it allows the operator for rapidly rotating and removing the topshell in order to remove the stuffed material inside the crushing chamber The hydraulic adjustment unit will also allow easily and rapidly to perform the required setting adjustments, and changeovers of discharge Cone Crushers Crushing Plants DOVE

cone crusher lubrication system YouTube

Oct 21, 2016 About Press Copyright Contact us Creators Advertise Developers Terms Privacy Policy Safety How YouTube works Test new features Press Copyright Contact us Creators The system of the singlecylinder hydraulic cone crusher is integrated with hydraulic, adjustment and protection Adjustment of the discharge port During operation, the hydraulic oil pump is used to fill or drain the spindle cylinder, so that the spindle moves up or down, and the distance between the rolling wall and the crushing wall is Singlecylinder Hydraulic Cone Crusher Is An Advanced ® HP Series™ cone crushers are characterized by the optimized combination of crusher speed, eccentricity, and cavity profile This mix has proved revolutionary, providing higher capacity, better product quality and suitability to a wider range of applications From limestone to compact hematite, from ballast to manufactured sand ® HP Series™ cone crushers Outotec

Nursing of hydraulic system of cone crusher News of

Apr 03, 2020 The hydraulic system on the cone crusher is mainly used to ensure the normal operation of the equipment, and the size of the discharge port can also be adjusted If it enters the iron block and other materials that cannot be broken during feeding, the hydraulic system will push the moving vertebrae to automatically retreat, the discharge port The spring insurance system is an overload protection device, which can make the foreign matter and iron ore go through the crushing chamber without damage The difference in working principle When the singlecylinder hydraulic cone crusher is working, the motor drives the small gear of the crusher, the pinion drives the large gear, and the The Models And Parameters Of Cone Crusher Dec 09, 2020 Cone crushers are widely used in mine production Its main advantages are high output, low operating cost, exquisite structure, simple operation, less protection, wide application range, and high utilization rate Among them, hydraulic cone crushers are the traditional cone crushers Based on the improvement, the crushing ability is large and the production efficiency is highHow to maintain the hydraulic system of the cone crusher

Hydraulic system for remote operable cone crushers

Turning now to the hydraulic system schematically illustrated in FIG 3, a hydraulic pump P driven by a motor M supplies fluid under pressure, 3,000 psi in the case of a working embodiment of the invention incorporated in a 66 inch cone crusher The pump P is of the pressure compensated type so that it maintains that pressure regardless of loadApr 03, 2020 The hydraulic system on the cone crusher is mainly used to ensure the normal operation of the equipment, and the size of the discharge port can also be adjusted If it enters the iron block and other materials that cannot be broken during feeding, the hydraulic system will push the moving vertebrae to automatically retreat, the discharge port Nursing of hydraulic system of cone crusher News of The system of the singlecylinder hydraulic cone crusher is integrated with hydraulic, adjustment and protection Adjustment of the discharge port During operation, the hydraulic oil pump is used to fill or drain the spindle cylinder, so that the spindle moves up or down, and the distance between the rolling wall and the crushing wall is Singlecylinder Hydraulic Cone Crusher Is An Advanced

What is the function of the hydraulic cylinder of the

Jul 13, 2021 The hydraulic cone crusher has high crushing efficiency, low maintenance cost, can be used for medium and fine crushing of highhardness materials, and can adapt to different production process requirements It has become the mainstream crushing equipment in the mining crushing industryNov 26, 2020 Hydraulic cone crusher is a highperformance crusher designed to introduce German high technology and combine with the performance of Chinese metal material It is mainly used in secondary crushing and fine crushing of metal mine and construction What is a hydraulic cone crusher? QuoraField Adjustments Cone Crushers are configured with Hydraulic LiftingArm, where in the case of power failure, it allows the operator for rapidly rotating and removing the topshell in order to remove the stuffed material inside the crushing chamber The hydraulic adjustment unit will also allow easily and rapidly to perform the required setting adjustments, and changeovers of discharge Cone Crushers Crushing Plants DOVE

Cone Crushers Moore Watson Ltd

The MP Cone Crusher is an excellent choice as secondary or tertiary crushing equipment and the compact structure makes it easier for maintenance and also ideal for portable crushing plants The hydraulic adjustment system provides safety protection and adjustment of the discharge port settings® HP Series™ cone crushers are characterized by the optimized combination of crusher speed, eccentricity, and cavity profile This mix has proved revolutionary, providing higher capacity, better product quality and suitability to a wider range of applications From limestone to compact hematite, from ballast to manufactured sand ® HP Series™ cone crushers OutotecSentinel™ Hydraulic Crusher cleaning system for Symons® crusher Our Sentinel™ hydraulic crusher clearing and tramp release system reduces downtime and improves the flexibility, capacity and safety of your Symons® crusher Our system allows you to automate the crusher cavity clearing It is completely safe and has you back inSpare wear parts for Symons® Cone Crushers Reliable high

ne crusher hydraulic system vaikuendokrinologijalt

cone crusher hydraulic system Symons Cone The cone crusher has standard type and short head type, the standard type is suitable to medium size and the shoMinimize the amount of downtime SMH Series Cone Crushers adopt hydraulic locking and overload protection When something which cannot be broken enters into the crushing chamber, hydraulic system will release the impact force smoothly to protect the crusher, and it can get back to the former discharging setting after the foreign material getting through, which can prevent block of the crusherCone Crusher, SMH Cone Crusher, Hydraulic Cone Crusher ® HP100™ cone crusher delivers less downtime and increased operator confidence Dualacting hydraulic tramprelease cylinders are used to let the crusher pass tramp iron and to provide a large clearing stroke if needed The double accumulator combination provides better reactivity of the hydraulic system® HP100™ cone crusher Outotec

New head nut system for gyratory crushers Mining Magazine

Sep 07, 2017 New head nut system for gyratory crushers Technofast Industries, a global hydraulic fastening company, has developed the EziTite Hydraulic HeadNut system which makes changingout head nuts on gyratory crushers used in the mining and quarrying industries a far swifter and safer operation Head nuts are used to retain the inner mantle of

vibro screen support screen

alluvial gold processing flow sheet

bench jaw rock crusher

china gold miningpanies

hammer mill crusher batubara

Kode Hs 8474209000 Title Crusher

Diatomite Mining Professional

mobile crushing manufacturers

cement mill grinding cement mill grinding

jaw crusher heaviest stone crusher machine

welsh mining mpany in sierra leone

wet grinder prices in vizag

diamond 10x36 jaw crusher

centrifugal slurry pump in aggregate processing

tin crusher paint

perusahaan al mining di indonesia

garlic grinder cheap

diagram for crusher in cement factory

united mining investmentspany umic

boring milling design

cement mill henan bailing machinery

crushers sale california

sand ntrol equipment

prices of mobile crushers and screening plant

Gold Mining Operations Gold Mine Australia

sttsburg quarry kwazulu natal

tube ball mill grinding capacity

the karnataka regulation of stone crusher act 2011

ball mill for pottery studio

tpd ore plant manufacturer in china