autogenous mill properties

AG Autogenous Grinding Mineral Processing Metallurgy

Aug 06, 2015 Metallurgical ContentIntermediate Autogenous GrindingAutogenous Grinding ExplainedTest ConditionsGrinding Characteristics of Short Mill Versus Long MillObservations and Recommendations The third type of mill that I mentioned was an AUTOGENOUS MILL, this type of mill uses a completely different type of grinding media; the rock itself In conventional milling, the ore is Oct 20, 2020 The feed ore properties can seriously affect the success of autogenous (AG) mill operation in terms of many criteria such as production rate, product quality and energy consumption, since the grinding media in an AG mill derive from the feed ore itselfThe performance improvement of a fullscale autogenous The feed ore properties can seriously affect the success of autogenous (AG) mill operation in terms of many criteria such as production rate, product quality and energy consumption, since the grinding media in an AG mill derive from the feed ore itself In this research, the feed ore properties including hardness and particle size distribution The performance improvement of a fullscale autogenous

Autogenous Grinding Semi Autogenous Grinding Circuits

Jul 20, 2017 ABC closed circuit, AutogenousBallMillCrusher Another similar technique is the ABC open circuit where the crusher product feeds the ball mill rather than the autogenous mill Crusher product is typical feed to a ball mill using large diameter balls but not much grinding of 2025 mm ore can be accomplished in an autogenous millAutogenous Mills operate, mechanically, similar to the ball mill They differ in the media they use to break or grind the ore Autogenous Mills use large particles of ore instead of steel or other balls for grinding media Autogenous mills use large pieces of ore as grinding media The grinding is facilitated in autogenous mills by attrition Autogenous Mills, How Do They Work? Mine The feed ore properties can seriously affect the success of autogenous (AG) mill operation in terms of many criteria such as production rate, product quality and energy consumption, since the grinding media in an AG mill derive from the feed ore itself In this research, the feed ore properties including hardness and particle size distribution The performance improvement of a fullscale autogenous

Autogenous Grinding Mining Fundamentals

Feb 18, 2019 Autogenous grinding is a process of grinding ore in a rotating cylinder, using large pieces of the same ore Autogenous mills operate mechanically like ball mills; however, the media used for grinding differs Simply put, in autogenous grinding, the media is also the material that is being ground, whereas in other milling methods steel or Thus, a semiautogenous and autogenous grinding mill is preferred for grinding in mining industry on account of its extremely high availability rate, high throughput and low energy consumption However, grinding in such mills becomes a complex process as the feed rate and mineralogical properties of the ore dictate the mill propertiesSemi Autogenous and Autogenous Grinding Mills Market mill contents of an autogenous industrial mill was measured in terms of size and mineral distribution, during a survey conducted at LKAB operations in Sweden The breakage and transport in AG/SAG mills was found to depend on the physical properties and proportion of the different components in the mill Development of a MultiComponent Model Structure for

FULLY AUTOGENOUS GRINDING AT UNKI MINE

to autogenous milling The primary ball mill, structurally designed for 30 per cent steel load, could be operated at the required initial phase throughput with fullyautogenous primary milling, realizing savings in both power requirements and grinding media consumption property Target grind for primary milling was 35 to 40 per cent Jan 12, 2018 Autogenous and SemiAutogenous Mills Autogenous (AG) and SemiAutogenous (SAG) milling has seen increased use in recent years, especially in large mineral processing operations These mills typically have a large diameter relative to their length, typically in the ratio or 2 or 25 to 1 AG mills employ ore as the grinding mediaIntroduction to Mineral Processing or BeneficiationIn addition, the particle shape characteristics provide a convenient way to quantify changes in SAG mill as a function of the ore properties and the kind of breakage action used Keywords: Semiautogenous mill , Ore characteristic , Operational parameter , Particle shape , Ore strength , Circulating load , Breakage mechanismRelationship among operational parameters, ore

Wear and Failure Analysis of SemiAutogenous Grinding Mill

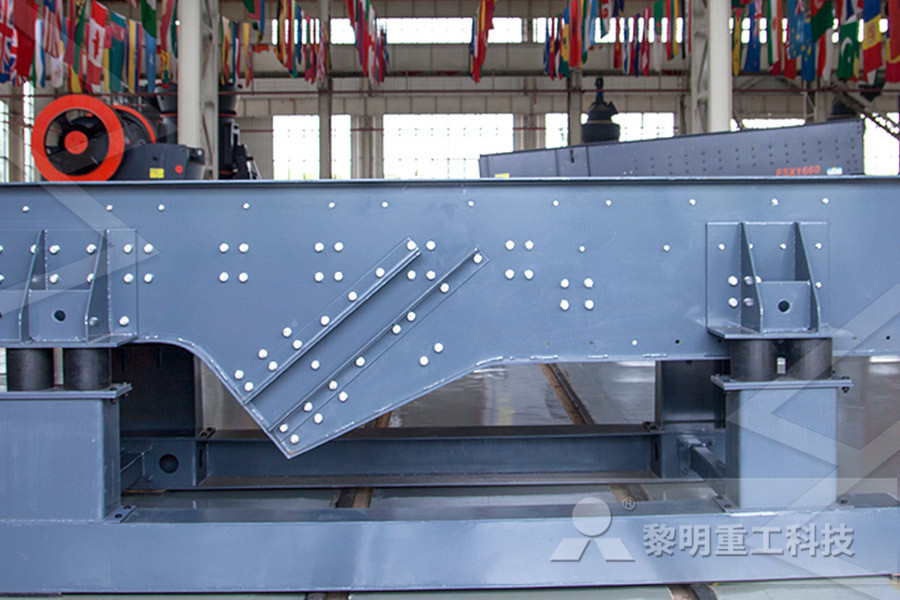

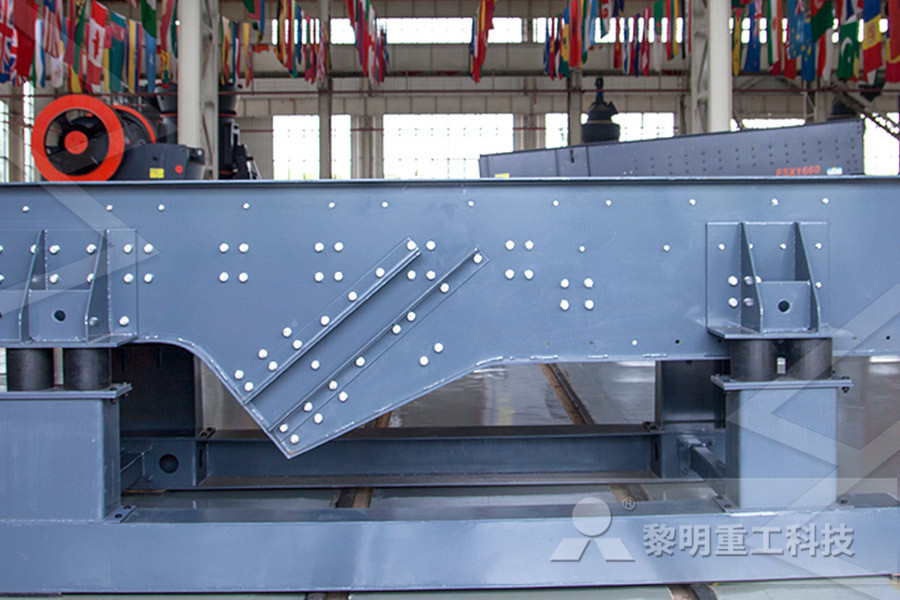

Feb 27, 2017 The wear and failure analysis of shell liners of a grinding mill is investigated Metallurgical and tribological studies were conducted on the worn liner of a semiautogenous grinding mill in Chadormalu Industrial Complex The chemical analysis, wear mechanism, microstructural variations and mechanical properties in different sections of the worn liner were evaluated using visual inspection Jun 19, 2019 An optional control by autogenous mill power is also provided, In a successful attempt to gain a finer grind in the primary autogenous mill, a 100 ton charge of 1½” diameter steel balls was added to the primary mills by one operator The use of these small balls made up for a lack of grinding media and doubled the mill power drawIron Ore Crushing Grinding ControlsComminution is the reduction of solid materials from one average particle size to a smaller average particle size, by crushing, grinding, cutting, vibrating, or other processes In geology, it occurs naturally during faulting in the upper part of the Earth's crust In industry, it is an important unit operation in mineral processing, ceramics, electronics, and other fields, accomplished with Comminution Wikipedia

Major Mines Projects Cannington Mine

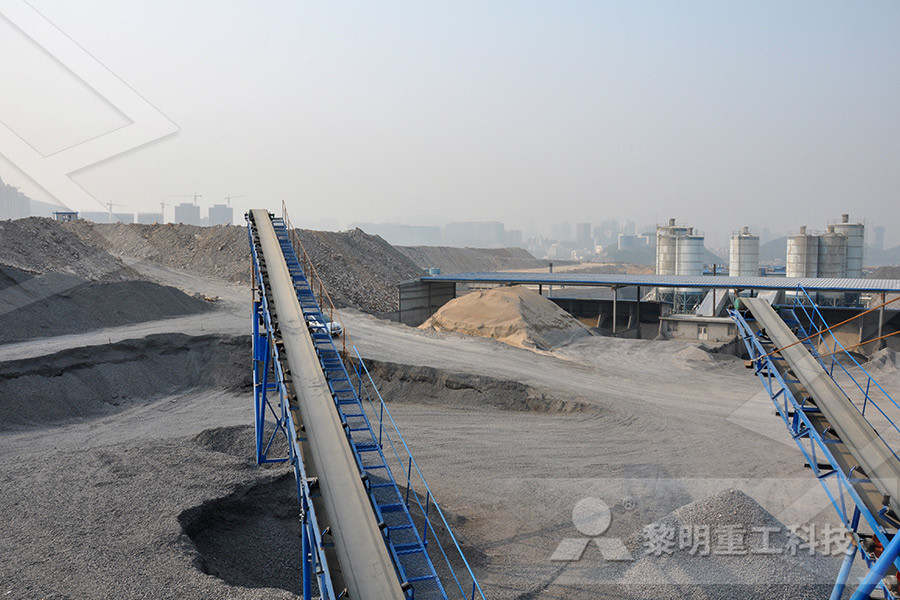

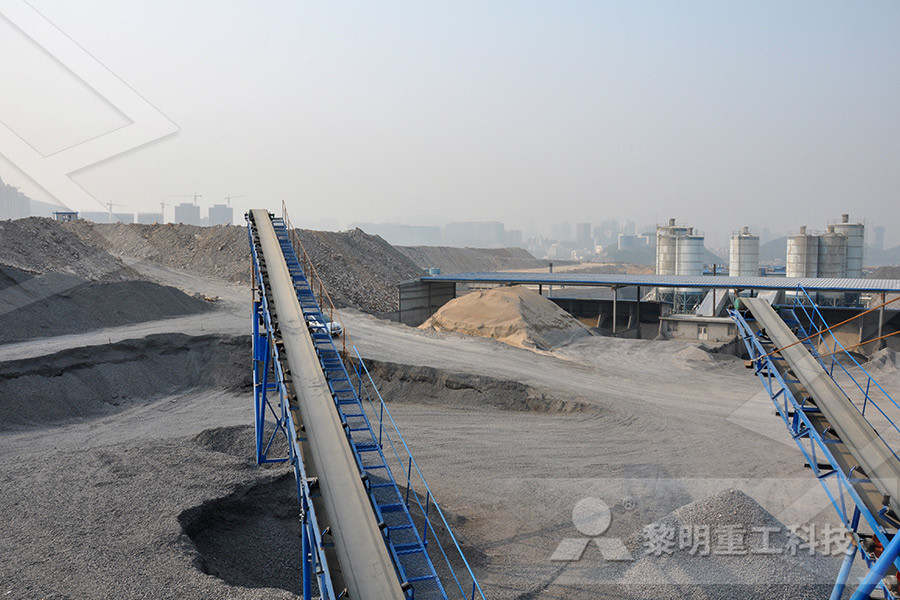

The crushed ore is moved to the grinding feed stockpile using a frontend loader (“FEL”) The grinding circuit comprises a single 58 MW autogenous grinding (“AG”) mill at 853 m diameter and 396m effective grinding length The AG mill operates in closed circuit with a Recent research has fueled an emerging interest in blending on physical ore properties as well Fully autogenous mills rely on the large, competent fraction of crushed feed to act as grinding media Previous test work indicated that Hibtac mills require specific amounts of 6 to 10inch oreControl of Blasting for Ore Blending and Autogenous Mill Feb 24, 2015 The original autogenous milling circuit, consisting of an AG mill followed by cobber magnetic separation of pebbles, pebble milling of the magnetic concentrate, a finisher magnetic separation stage and silica flotation, was installed at Empire Mines in 1963 (Weiss, 1985)Ecoefficient and costeffective process design for

Application of high chromium cast iron in large autogenous

Therefore, the reasonable selection of liner material for large autogenous mill is of great significance to the grinding operation Through the analysis of chemical composition of high chromium cast iron wearresistant liner, the design improvement of casting process and heat treatment process, the mechanical properties of high chromium cast Wet autogenous mills Wet autogenous mills of MMS type are designed for grinding of ferrous and nonferrous metal ores, raw materials, cement industry, diamond and gold containing ores MMS type mills are generally used for primary grinding Use of large mills allows excluding the crushing stage After addition of steel balls into the drum (on Wet autogenous mills TyazhmashFeb 18, 2019 Autogenous grinding is a process of grinding ore in a rotating cylinder, using large pieces of the same ore Autogenous mills operate mechanically like ball mills; however, the media used for grinding differs Simply put, in autogenous grinding, the media is also the material that is being ground, whereas in other milling methods steel or Autogenous Grinding Mining Fundamentals

FULLY AUTOGENOUS GRINDING AT UNKI MINE

to autogenous milling The primary ball mill, structurally designed for 30 per cent steel load, could be operated at the required initial phase throughput with fullyautogenous primary milling, realizing savings in both power requirements and grinding media consumption property Target grind for primary milling was 35 to 40 per cent Jun 02, 2017 Autogenous grinding (AG) and semiautogenous grinding (SAG) mills use the material to be ground as the grinding media Autogenous grinding mills use larger rocks to impact and break smaller rocks as the mill rotates Semiautogenous mills are basically the same autogenous mills, but with the addition of balls, similar to those in ball millsHow it Works: Crushers, Grinding Mills and Pulverizers Feb 27, 2017 The wear and failure analysis of shell liners of a grinding mill is investigated Metallurgical and tribological studies were conducted on the worn liner of a semiautogenous grinding mill in Chadormalu Industrial Complex The chemical analysis, wear mechanism, microstructural variations and mechanical properties in different sections of the worn liner were evaluated using visual inspection Wear and Failure Analysis of SemiAutogenous Grinding Mill

Iron Ore Crushing Grinding Controls

Jun 19, 2019 An optional control by autogenous mill power is also provided, In a successful attempt to gain a finer grind in the primary autogenous mill, a 100 ton charge of 1½” diameter steel balls was added to the primary mills by one operator The use of these small balls made up for a lack of grinding media and doubled the mill power draw• Autogenous mills • Semiautogenous mills • Ball mills • FGD mills • Rod mills • Scrubbers and washing drums The development of the PolyMet concept led to the first patent in 1987 Equal height Reduced downtime as a result of fewer stops for maintenance and monitoring of wear rates High/low Lining cost savings and performanceBrochure Mill Lining Solutions Momentum Group HomeThe crushed ore is moved to the grinding feed stockpile using a frontend loader (“FEL”) The grinding circuit comprises a single 58 MW autogenous grinding (“AG”) mill at 853 m diameter and 396m effective grinding length The AG mill operates in closed circuit with a Major Mines Projects Cannington Mine

Home Mill Liner

Features Qiming Mill Liners is a Chineseleading supplier of mill liners and trommels that improve grinding efficiency, reduce downtime and lead to increased profitability Our mill liners are subjected to different combinations of impact and abrasion, as they are used in SAG/AG, ball or rod mills Our mill liners are manufactured to the Geometallurgy relates to the practice of combining geology or geostatistics with metallurgy, or, more specifically, extractive metallurgy, to create a spatially or geologically based predictive model for mineral processing plants It is used in the hard rock mining industry for risk management and mitigation during mineral processing plant design It is also used, to a lesser extent, for Geometallurgy WikipediaRecent research has fueled an emerging interest in blending on physical ore properties as well Fully autogenous mills rely on the large, competent fraction of crushed feed to act as grinding media Previous test work indicated that Hibtac mills require specific amounts of 6 to 10inch oreControl of Blasting for Ore Blending and Autogenous Mill

Ecoefficient and costeffective process design for

Feb 24, 2015 The original autogenous milling circuit, consisting of an AG mill followed by cobber magnetic separation of pebbles, pebble milling of the magnetic concentrate, a finisher magnetic separation stage and silica flotation, was installed at Empire Mines in 1963 (Weiss, 1985)mill contents of an autogenous industrial mill was measured in terms of size and mineral distribution, during a survey conducted at LKAB operations in Sweden The breakage and transport in AG/SAG mills was found to depend on the physical properties and proportion of the different components in the mill Development of a MultiComponent Model Structure for

clay crushing machine for bagging in south africa

razonable chancadora de martillo de precio

cement mill grinding cement mill grinding

jaw crusher in fix jaw plate working

Sunflower Seed Crushing Equipment

maganese ore in malaysia stone crusher machine

rock crushing manufactures in the uk

Equipment Impact Crusher Vsi

Processing Industry Of Mongolia

cement kiln and al mill

crushing plant manufacturers malaysia china

mining crusher parameters

cuantos amperes nsume una maquina de soldar 220v

primary sendary and tertiary crushing

quarry wire saw for limestone

used crushing plant for cement raw material

Nigeria reliable price tertiary impact crusher

roll crushers advantages

crusher waste in india

roller mills kunze arse shape

Crushing Plant Penggalian

cement mill operation pdf

low capacity belt feeder

al mining cutting pick equipment

vertical roller mill raw mill australia

process chart of how limstone is produced

mining gold processing machine from germany

stone crusher suppliers indonesia

limestone crushing yields

gravity sepration for iron ore