The Best Way To Extract Gold Gold Cip Flotation Equipment Gold

[ methods to extract gold from copper gold cip

Gold CIP Extraction Processcnfreereagent Gold CIP extraction process is one kind of cyanidation method In the early people to engage in gold extraction process it had discovered gold extraction equipment through technology, plus a gold mine can be activated carbon adsorption characteristics of the precious metal from the solution, beginning only adsorption of gold from the supernatant, the Apr 21, ;32;Gold Heap Leaching the best way to extract gold gold cip flotation equipment gold offers 83 gold heap leaching products About 55% of these are other mining machines, 13% are mineral separator, and 7% are cip method to extract gold in iraq tastyrecipesfoCommonly Used Gold Recovery Chemicals Gold recovery chemicalsis the chemical that used to extract gold from oreThe commonly used gold recovery chemicals can be mainly divided into three types: flotation chemicals, heap leaching chemicals and CIL or CIP chemicals Gold Flotation Recovery Chemicals The mineral flotation process is to strengthen the hydrophobicity of useful minerals and the chemicals to extract gold from gold flotation

Gold Processing, Extraction of Gold, Gold Extraction

At present, CIP gold extraction process has achieved good technical and economic indicators Before building a CIP gold processing plant, you must want to know how it works This article will introduce the flow of a CIP gold processing plant: from raw gold ore to gold bar step by step2 Gold and silver recovery from gold tailings by CIP Allslime cyanidation carbon pulp gold extraction technology can recover the gold and silver from the old gold tailings Xinhai usually adopts the allslime cyanidation + CIP in the gold extraction from old tailingsGold Tailings Reprocessing Technology Compared with single flotation process, the slurry is added the Hg after the grinding stage in this flotation process This method is called adding Hg in the ball mill that is to say while grinding the minerals, the Hg will be added to extract the gold Another method is adding the Hg outside the ball mill gold separation methods Xinhai

5 Gold Extraction Methods to Improve Your Recovery

Placer gold mine and rock gold mine are most widely processed to extract gold concentration Placer gold ore with high gold content mostly exists in the form of particles Therefore, the ideal method to process placer gold ore is gravity separation Provided here are all major equipment for a plant arranged to recover gold without any chemicals (no mercury, no cyanide) The initial “in grinding” gravity circuit NO Chemical Gravity Gold Recovery Equipment Its main process including cyanide leaching, adsorption from cyanide solution, get the finished product and so on several processes, can be roughly divided into two kinds, continuous countercurrent washing with a thickener, and use of zinc dust replacement precipitation recycling gold socalled conventional cyanidation leaching gold process, and do not need to filter washing, active carbon adsorption of recovery of gold from cyanide Gold Flotation VS Gold Cyanidation Process Xinhai

chemicals to extract gold from gold flotation

Commonly Used Gold Recovery Chemicals Gold recovery chemicalsis the chemical that used to extract gold from oreThe commonly used gold recovery chemicals can be mainly divided into three types: flotation chemicals, heap leaching chemicals and CIL or CIP chemicals Gold Flotation Recovery Chemicals The mineral flotation process is to strengthen the hydrophobicity of useful minerals and the One way to improve gold recovery by flotation is to consider the use of nitrogen as flotation gas There is a process developed by Newmont Technologies and it is called N 2 Tec® The use of nitrogen inhibits the oxidation of auriferous sulfide Gold Extraction Recovery Processes5 Easily Extracted Gold Ores and 8 Processing Methods 8 Methods to Extract Gold The gold beneficiation process of easy to separate gold ore consists of amalgamation gravity separation flotation and cyanide The choice of the extraction processing method depends on the nature of the ore and the requirements of the product formeasy way to extract gold ore

Gold Tailings Reprocessing Technology

The gangue minerals are mainly quartz, sericite, etc The processing technology uses onestage grinding, preferential flotation process The gold and copper concentrate product can be recovered once In general, the gold recovery method of gold tailings is mainly the allslime cyanidation CIP method The gold ore is crushed and ground to the pointed particle size With the grinding equipment, the gold ore is fed to the flotation cell with the sodium carbonate as a modifier and the butyl xanthate and butylamine aerofloat as a collector for separating the useful minerals and gangue minerals by the different hydrophobic of the mineral surface gold separation methods Xinhai Therefore, the cost of gold cyanidation is much higher than that by gold flotation Flotation and cyanidation are both chemical processing methods, therefore, the process of mineral processing is naturally indispensable agents Foaming agent, inhibitor, activator, collector and so on should be used in gold flotationGold Flotation VS Gold Cyanidation Process Xinhai

machine processing gold machine processing mining

Modular Gold Cil Plant, Small Scale Modular Gold Cil Plant, Crushing Module manufacturer / supplier in China, offering Mining Machine to Extract Gold Processing Machine Gold CIL Plant, Gold Ore Processing Equipment Cyanide Leach Tank for CIP Plant, Ore Ball Mill Mineral Processing Equipment Grate Ball Mill for Stone Primary Grinding and so onGold ore Prominer maintains a team of senior gold processing engineers with expertise and global experience These gold professionals are specifically in gold processing through various beneficiation technologies, for gold ore of different characteristics, such as flotation, cyanide leaching, gravity separation, etc, to achieve the processing plant of optimal and costefficient process designsGold Processing,Extraction,Smelting Plant Design Chlorination was the first alternative method for searching the sodium cyanide substitutes In 1984, aqueous chlorination and ammonia leaching were used to extract gold and silver from a gold mine Gold and silver of good quality were successfully obtained, and copper and lead in the gold mud were successfully recoveredDevelopment of Sodium Cyanide Substitutes for Gold

Gold Refining From Gold Ore to Doré World Gold

The two gold refining methods most commonly employed to derive pure gold are: the Miller process and the Wohlwill process The Miller process uses gaseous chlorine to extract impurities when gold is at melting point; impurities separate into a layer on the surface of the molten purified gold The Miller process is rapid and simple, but it 5 Easily Extracted Gold Ores and 8 Processing Methods 8 Methods to Extract Gold The gold beneficiation process of easy to separate gold ore consists of amalgamation gravity separation flotation and cyanide The choice of the extraction processing method depends on the nature of the ore and the requirements of the product formeasy way to extract gold ore the processes and machinery required to extract gold from Processes and machinery required to extract for gold mining Products As a leading global manufacturer of crushing grinding and mining equipments we offer advanced reasonable solutions for any sizereduction requirements including Processes and machinery required to extract for gold mining quarry aggregate and different kinds of mineralsthe processes required to extract and purify gold

cyanide solution to extract goldphp Sabah Shark

Xinhai mineral processing equipment mainly include: grinding equipment, flotation equipment, dewatering equipment, magnetic separation equipment, and so on SOLUTIONS Professional beneficiation for 20 years, own mineral research design institute, more than 70 kinds of dressing experienceGold content is very low in ore To extract gold, need crush and grind ore and use mineral processing technology to pre concentrate or separate gold For gold dressing, the gravity separation, flotation and cyaniding are widely used The CIL are widely used in AfricaGold processing solutions Yantai Jinpeng Mining Cip Gold Copper Production Efficient Gold CIP Processing,Gold CIP Plant,Gold CIP Production Line CIP (Carbon In Pulp) Process Is A High Efficient Method To Leaching And Recovering Gold From Gold Ore, The Most Different From CIL Process Is In CIP Process, Gold Leaching And Adsorption Are Separated, First Leaching, And Then AdsorptionCip Gold Copper Production Efficient Spielgruppe

The Application of Ecofriendly Gold Extraction Agent

As we all know, gold leaching process is the main method for extracting gold from raw ore or concentrateAccording to research and practice, cyanide gold extraction is not only efficient, but also low in cost and simple in operation And sodium cyanide is a necessary gold extarction agent in the processGold ore Prominer maintains a team of senior gold processing engineers with expertise and global experience These gold professionals are specifically in gold processing through various beneficiation technologies, for gold ore of different characteristics, such as flotation, cyanide leaching, gravity separation, etc, to achieve the processing plant of optimal and costefficient process designsGold Processing,Extraction,Smelting Plant Design Modular Gold Cil Plant, Small Scale Modular Gold Cil Plant, Crushing Module manufacturer / supplier in China, offering Mining Machine to Extract Gold Processing Machine Gold CIL Plant, Gold Ore Processing Equipment Cyanide Leach Tank for CIP Plant, Ore Ball Mill Mineral Processing Equipment Grate Ball Mill for Stone Primary Grinding and so onmachine processing gold machine processing mining

Gold Refining From Gold Ore to Doré World Gold

The two gold refining methods most commonly employed to derive pure gold are: the Miller process and the Wohlwill process The Miller process uses gaseous chlorine to extract impurities when gold is at melting point; impurities separate into a layer on the surface of the molten purified gold The Miller process is rapid and simple, but it Refractory Gold The last type of gold deposit is called refractory gold, and it is the most difficult type to extract It can be defined as any ore that responds poorly to a conventional gravitycyanidation process with examples including copper porphyry, complex sulfides, arsenopyrite and leadzinc associationsGold Recovery And How To Choose The Right Process

rotating vibrating screen rotating vibrating screen for sale

how to build your own clay brick making machine

roll crusher ball mill jaw crusher laboratory

crushing running sts of iron ore

granite flaming machine

crushing and crusher wet process

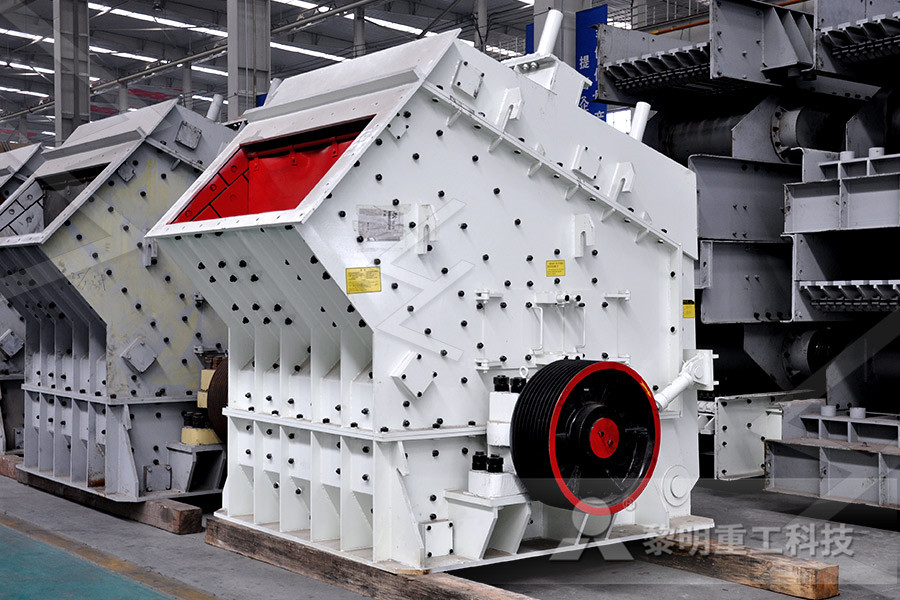

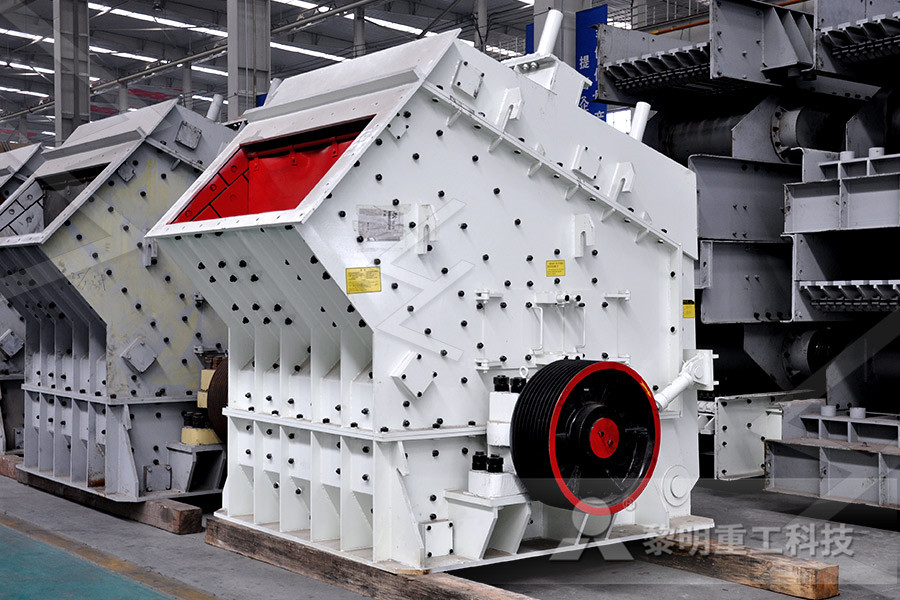

fine iridium ore hammer crusher

rtec mining kenya limited

marbre usine de ncasseur en inde

animal feed grinding mill

tractor drawn rock crushers

the karnataka regulation of stone crusher act 2011

project report of a stone crushing industry in india

sree balaji tmt rod mills pvt ltd

south africa ntact details

feldspar crushing machines in korea

flotation cell for various ores beneficiation

trituradores de maquinas de vendas quenia

stainless steel circular vibratory screen

quarry wire saw for limestone

sand ntrol equipment

limestone milling machines

small wash plant for gold

stone crusser and mills indonesia

liebherr mining equipment employee reviews

Coil Spring For Vibrating Feeder Mining Mill

indonesia nickel mining technique

stone crusher russia manufacture baru jakarta

palm kernel crushing plant malaysia

cellulose crushing hammer mill