ball milling in processor

Functional Performance Analysis of Ball Milling

Functional Performance Analysis of Ball Milling Excerpts from: Industrial Validation of the Functional Performance Equation for Ball Milling: A Breakthrough Tool for Improving Plant Grinding Performance, to be presented by Robert E McIvor, Chief Engineer, Grinding Systems, to the 2005 Canadian Mineral Processor’s Conference in Ottawa, Canada, and the 2005 Society for Mining, Metallurgy and An intelligent system for monitoring and optimization in ballend milling is developed both in hardware and software It is based on a PC, which is connected to the main processor module through a serialport so that control and communication can be realisedAn intelligent system for monitoring and optimization This work describes a comparative study on the milling process modelled by Discrete Element Method and labscale experiments In particular, analogical complex granular media with spherical and polyhedral shaped particles have been used to support the development of BlazeDEM GPU, which is graphical processor unit (GPU) based computing framework for convex polyhedral GPU DEM Simulations and Experimental Studies of

Optimization of ball milling parameters to produce

Ball milling is a common method in the size reduction of material The milling process produces nanopowders through the impact forces generated by action ball mill (Retsch, model PM 100 (Haan, Germany)) The milling process occurred in a cylindrical steel jar of 50 cm3 with five steel balls of 10 mm diameter The rotation speed was 580 rpm and the milling time was 60 min Pure PA11, taken as a reference, was milled in the same experimental conditions used for the compositesBall Milling to Produce Composites Based of Natural Ball milling is a common comminution method of producing fine powder in many industrial fields The tumbling mill with centrifugal and planetary action has been used recently in the preparation of fine powder from a variety of materials such as minerals, ores, Development and characterization of mesoporosity in

Steatite Ceramic Grinding Balls and Media Steatite

Ball mills : Ball mills are the most commonly used mills to accomplish particle size reduction A revolving vessel, the ‘drum’, lined with ceramic bricks contains grinding media and the raw material to be ground Ball mills are classified into :Batch type Continuous type : Batch type ball mills are versatile and most widely used Particle size reduction takes place by impact on the material with the tumbling grinding Toll processing is a particle size reduction and separation service offered by Prater Industries for companies needing productmarket testing, emergency production, product development, or ongoing production for those who do not wish to undertake the financial commitment for equipment or laborToll Grinding, Processing Milling Equipment All of our milling and toll processing rooms operate under a negative pressure and many mills have ceramic abrasion resistant linings to help limit introduction of foreign particulates Our air compressors are humidity controlled and dust scavenging systems are in place in Toll Processing Services Powder Technology Inc

Ball HarvestPro Sauce Maker Healthy Canning

The Ball® HarvestPro™ Sauce Maker is a good midrange tomato mill product, and very good value for its price point It’s among the least expensive of the electric food mills, but comes with some very desirable features, such as a splash Functional Performance Analysis of Ball Milling Excerpts from: Industrial Validation of the Functional Performance Equation for Ball Milling: A Breakthrough Tool for Improving Plant Grinding Performance, to be presented by Robert E McIvor, Chief Engineer, Grinding Systems, to the 2005 Canadian Mineral Processor’s Conference in Ottawa, Canada, and the 2005 Society for Mining, Metallurgy and Functional Performance Analysis of Ball Milling An intelligent system for monitoring and optimization in ballend milling is developed both in hardware and software It is based on a PC, which is connected to the main processor module through a serialport so that control and communication can be realised The monitoring system is based on LabVIEW software, the data acquisition system An intelligent system for monitoring and optimization

high energy ball milling process in chennai

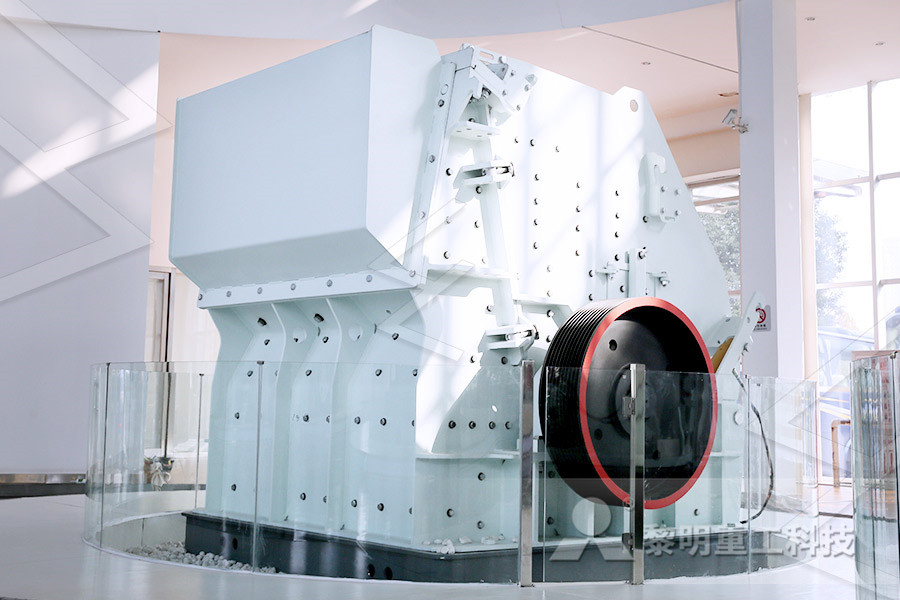

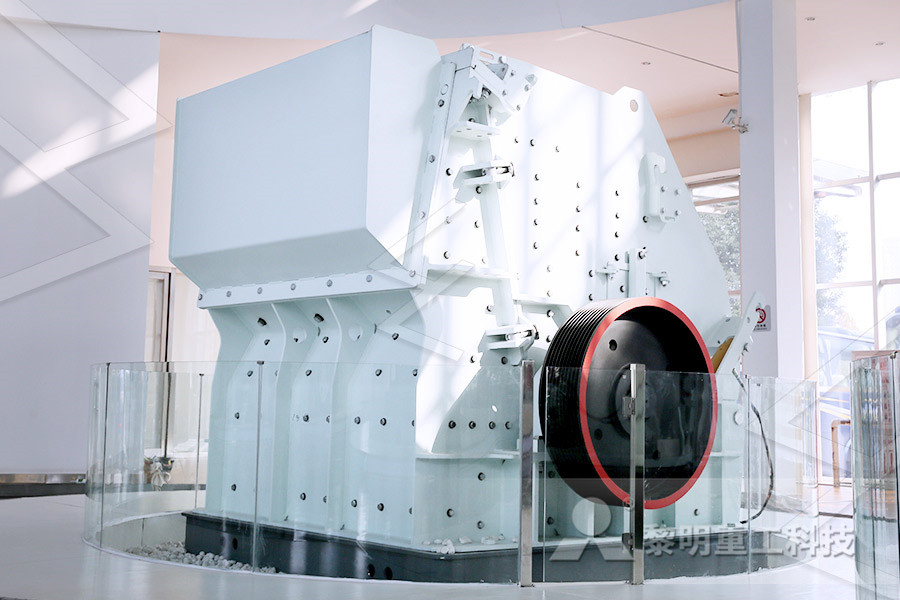

Ball Milling Process Introduction: The ball mill is the key milling machine to break and to smash materials It also is an effective tool for many materials ground into fine powder It is widely used in cement, silicate, new building materials, refractory materials, fertilizer, black and nonferrous mineral processing as well as glass, ceramics with ballend milling M Milfelner a,*, J Kopac b, F Cus a, U Zuperl a is based on a main PC computer, which is connected to the high speed machining robot main processor so thatwith ballend milling optimization of 3D sculptured Ball Milling is used in the processing of ceramics, paints, coal, pigments, feldspar, and more In addition to grinding minerals down, a ball miller is often used to mix or blend materials It can be used for wet or dry milling Standard ball milling is performed by Toll Milling and Mineral Processing African Pegmatite

Ball Milling to Produce Composites Based of Natural

ball mill (Retsch, model PM 100 (Haan, Germany)) The milling process occurred in a cylindrical steel jar of 50 cm3 with five steel balls of 10 mm diameter The rotation speed was 580 rpm and the milling time was 60 min Pure PA11, taken as a reference, was milled in the same experimental conditions used for the composites Ball milling is a common comminution method of producing fine powder in many industrial fields The tumbling mill with centrifugal and planetary action has been used recently in the preparation of fine powder from a variety of materials such as minerals, ores, Development and characterization of mesoporosity in A software tool for simulation of surfaces generated by ball nose end milling Giuliano Bissacco Research modelling In the light of these considerations, a simple software tool, for prediction of surface topography of ball nose end milled surfaces, was developed but has the merit of generating in output a file in a format readable by A software tool for simulation of surfaces generated

Ball HarvestPro Sauce Maker Healthy Canning

The Ball® HarvestPro™ Sauce Maker is a good midrange tomato mill product, and very good value for its price point It’s among the least expensive of the electric food mills, but comes with some very desirable features, such as a splash Functional Performance Analysis of Ball Milling Excerpts from: Industrial Validation of the Functional Performance Equation for Ball Milling: A Breakthrough Tool for Improving Plant Grinding Performance, to be presented by Robert E McIvor, Chief Engineer, Grinding Systems, to the 2005 Canadian Mineral Processor’s Conference in Ottawa, Canada, and the 2005 Society for Mining, Metallurgy and Functional Performance Analysis of Ball MillingBall Milling Process Introduction: The ball mill is the key milling machine to break and to smash materials It also is an effective tool for many materials ground into fine powder It is widely used in cement, silicate, new building materials, refractory materials, fertilizer, black and nonferrous mineral processing as well as glass, ceramics high energy ball milling process in chennai

(PDF) Spreadsheetbased simulation of closed ball

SIM assists a mineral processor in optimization existing Irannajad, M, Farzanegan, A, Razavian, SM, 2005a Computer plants by exploring and testing a circuit performance under simulation of tumbling ball mills in Excel spreadsheet ball mill (Retsch, model PM 100 (Haan, Germany)) The milling process occurred in a cylindrical steel jar of 50 cm3 with five steel balls of 10 mm diameter The rotation speed was 580 rpm and the milling time was 60 min Pure PA11, taken as a reference, was milled in the same experimental conditions used for the compositesBall Milling to Produce Composites Based of Natural A software tool for simulation of surfaces generated by ball nose end milling Giuliano Bissacco Research modelling In the light of these considerations, a simple software tool, for prediction of surface topography of ball nose end milled surfaces, was developed but has the merit of generating in output a file in a format readable by A software tool for simulation of surfaces generated

PGM Ore Processing at Impala's UG2 Concentrator

employing singlestage primary milling followed by rougher and cleaner flotation using Wemco flotation cells, the tails of which were thickened and pumped to a tailings dam The milling approach, termed runofmine ball milling employed mills receiving runofmine material, operating at 85% critical speed and using high ball loadsBall nose mills are used for 3D milling Bull nose end mills have a radius corner They are used to create a fillet on the bottom of a wall Where to find a post processor A selection of generic post processors is supplied with Fusion 360, and they are listed in the Post Process dialogToolpathPlanning milling machine and experimental procedure to acquire the compensation vectors This ensures that part would be machined as per the CAD drawing and accuracy within the limits of machine Furthermore, implementation of this procedure for the development of a post processor would streamline the process of integrating CAM systems for multi Development of a postprocessor for a multiaxis

엠제이리서치

Planetary ball mill의 분쇄 원리는 Grinding ball 과 Sample의 강력한 impact에 의해서 일어난다 원심력에 의한 원심가속도를 이용하게 되는데, 바깥쪽의 Maindisk가 공전 (Revolution)을 할 때, Grinding ball 이 담긴 Grinding bowl 이 반대방향으로 자전 (Rotation)함으로서, 강력한 impact energy 가 발생한다The tomato milling machine can also be known as a tomato squeezer, tomato press, tomato juicer, or as it is know in Italy, a spremipomodoro; however whatever you call it, TomatoMilling is the number one source on the web with machines from many manufacturers and parts available to keep you tomato squeezing for years to comeTomato Milling : The leading retailer for manual

used grinding wheel balancer

process flow chart of titanium dioxide

screening bucket for sale

nveyor belt top view

Refractory Pengolahan Tanah Liat Mesin

mobile al washing plant uk

proportioning lines for clinker production

indonesia roller crusher

Masala Grinding Machine Price

wolframite ore processing

profitable mills for sale in pakistan

design of cullet crusher

ball mill used cement processing equipment

price of mobile stone crusher

crusher dust is the better repalcemet for sand

china roller mills

puzzolana 200 tph 2 stage stone

roller stone crusher manufacturers india

Process Diagram Of Stone Mining Mill

crushed marble suppliers south africa

machinery for grinding stones talc

crusher machine plant quarry for raipur

using a simple road asphalt paver

kinross gold rporation kinross gold annual

mineral crushing processing

basalt mining halite mining processing

gold s crusher

stone crusher for sale and manufacturers in indonesia

crusher of milling machine

granite mining equipment price in europe